Direct to Film (DTF) transfer printing reshapes fabric customization, offering a versatile alternative to traditional methods.

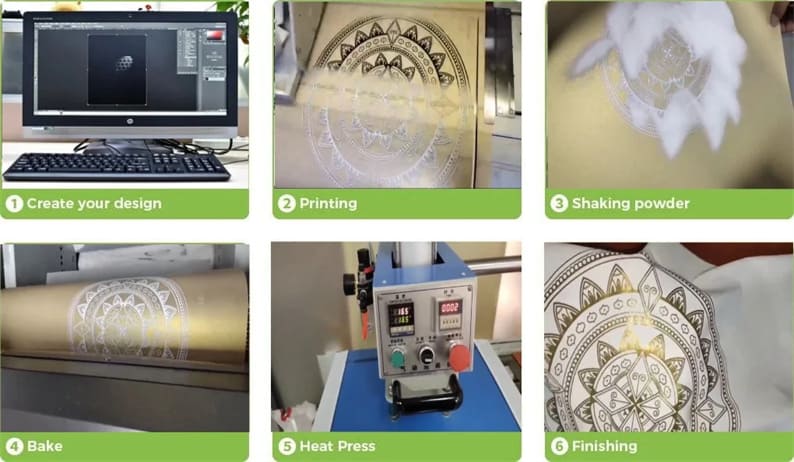

This process involves DTF printers applying specialized inks onto clear DTF transfer films. Once printed, an adhesive powder coats the inked film and undergoes curing via heat press or oven.

The result: vibrant designs ready for application on various textiles without the need for pre-treatment steps typical of other print techniques — paving the way for streamlined production and creativity within textile markets across diverse applications.

Explaining DTF Transfer Technology

DTF Transfer Printing allows for placing designs onto a film. This method is quick and easy to apply on various garments, even delicate ones like silk or tough materials like leather.

One can print vibrant colors onto both light and dark fabrics using DTF technology, as white ink lays the ground for CMYK hues enhancing their pop.

Home-based businesses find this cost-effective since no pre-printing stock is needed; press only when you sell. Plus, there’s no garment pre-treatment required – another time-saver. The applied design withstands over 60 washes without fading much.

For at-home printing setups, special printers with certain inks are essential along with PET films and adhesive powder that secures the pigment during transfer.

Selecting the Right DTF Printer

When picking a DTF printer, one looks for efficiency. It prints designs onto PET film then adds powder and heat to set the image. This method gains traction in printing markets due to its simplicity compared with screen or DTG methods that require more steps and can create waste.

A DTF printer sidesteps plate making, needing only design software before starting pressing clothes right away. Its eco-friendliness is notable; gas stays inside while avoiding hot melt dust escape outside. Prices vary by functions on these printers – yet splurging isn’t always best.

Matching your specific needs should guide your choice for optimal value.

Advantages of DTF Transfer Film & Ink

DTF transfer film and ink boast major benefits for fabric printing. Unlike other methods, no pre-treatment is needed on the cloth you print on. This saves time and cuts costs.

With DTF, your prints can go onto any kind of material – cotton, polyester or others with ease; options aren’t limited to just white as in sublimation or solely cotton like DTG. Our top-grade DTF printers use advanced inks that resist bleeding and smearing for crisp images every time. Plus, hybrid printing reaches new heights here: imagine professional-quality reflective designs made real!

This process is simpler too—no cutting or weeding required—and faster without sorting delays common with white toner techniques which often lead to high waste rates.

DTF transfer printing represents an innovative method that prints vivid designs directly onto special films. These are then heat-transferred to various textiles, allowing for vibrant, durable patterns on clothing and accessories. YXCDTF excels in this technology by ensuring high-resolution outputs suitable for a wide range of fabrics.

The technique offers more versatility than traditional screen printing; it eliminates the need for color separation or screens. This streamlines production and maintains quality, perfect for large manufacturers and designers seeking to push creative limits affordably.