Stable DTF Film

for Consistent Quality & Cost-Efficient Production

YXCDTF DTF Film is engineered for stable ink absorption, clean release, strong adhesion and long-term durability.

Designed to reduce printing failures, rework and after-sales costs, our DTF film supports efficient, scalable textile production for professional printers and garment manufacturers.

DTF printing is not just about ink.

It is about fabric behavior, powder bonding, and peeling timing.

In textile production, film performance defines speed, consistency, and garment quality.

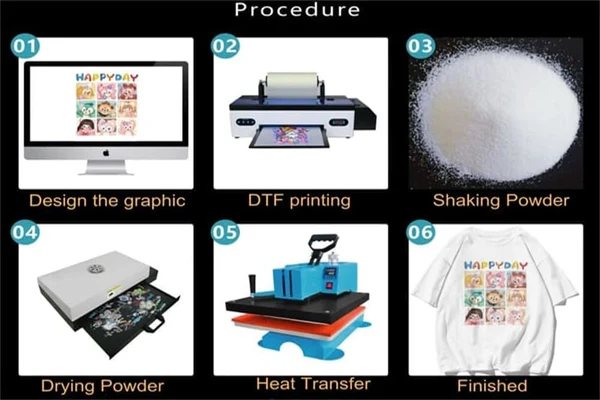

What Is DTF Transfer Film?

DTF Transfer Film is a specially coated PET film used in Direct to Film printing for textile applications.

The film receives printed ink and adhesive powder, then transfers the image onto fabric through heat pressing.

Film quality directly affects ink anchoring, powder adhesion, peeling behavior, and final wash durability.

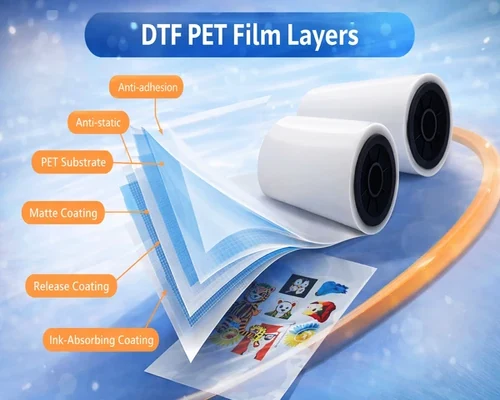

Cost-effective Film Structure for Textile Production

YXCDTF DTF film is developed to deliver consistent print results across different printers, inks and production environments. With optimized coating structure and controlled surface tension, our film ensures smooth ink laydown, clear details and reliable color output—even in long-run or high-volume printing.

PET Base Film

(Stability Under Heat)

Provides dimensional stability during printing and heat pressing, preventing shrinkage and deformation.

Functional Coating Layer

(Ink & Powder Balance)

Engineered coating ensures proper ink absorption and controlled powder adhesion.

Optional Anti-Static Back Coating

Reduces static during printing and feeding, improving workflow stability in high-speed production.

Clean Transfer, Reduced Rework & Lower After-Sales Risk

Our DTF film minimizes powder residue and adhesion issues, reducing reprints, waste, and overall production and after-sales costs.

Peeling Logic: Hot vs Cold DTF Film

Designed for process compatibility and efficiency, YXCDTF DTF film offers hot peel (zero-second) and cold peel options, supporting stable, predictable output in both sampling and mass production environments.

Hot Peel DTF Film

- Peeled immediately after heat pressing

- Faster production rhythm

- Suitable for high-efficiency workflows

Cold Peel DTF Film

- Peeled after cooling

- More forgiving transfer behavior

- Suitable for detailed graphics and thicker ink layers

Supporting Note: Peeling logic should be selected based on fabric type, ink load, and production rhythm.

Single-Sided vs Double-Sided DTF Film

When selecting DTF film, understanding the difference between single-sided and double-sided options is essential for stable printing results and production efficiency.

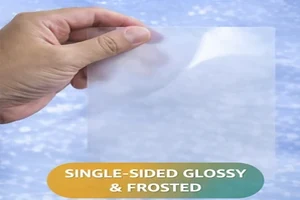

Single-Sided DTF Film

- Good ink absorption and color performance

- Lower material cost

- Best for small to mid-scale production&designs

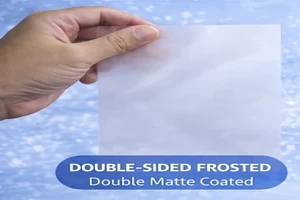

Double-Sided DTF Film

- Improve feeding stability during high-speed printing

- Reduce static and film shifting

- Enhance overall production consistency

Decision Guidance: Single-sided DTF film suits cost-sensitive projects, sampling, and low-to-medium volumes, while double-sided DTF film is ideal for mass production, automated workflows, and maximum stability.

Printing & Transfer Performance

Engineered for consistent results across production runs

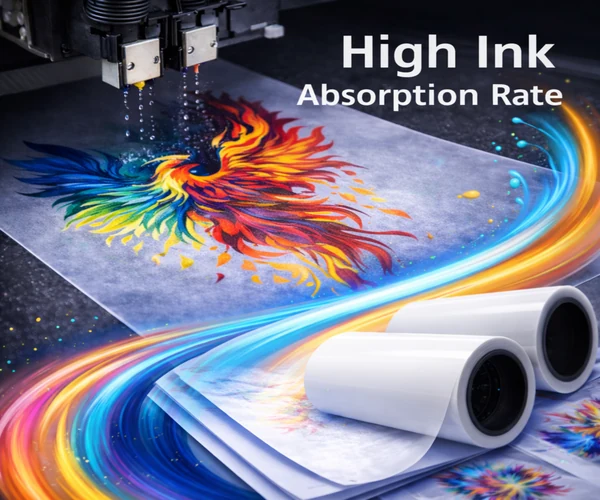

Stable Ink Reception

Consistent ink absorption for uniform color reproduction

Balanced Powder Adhesion

Optimal powder bonding without excessive adhesive buildup

Clean Image Transfer

Sharp detail reproduction with minimal ink migration

Reliable Peeling Consistency

Predictable release behavior across different conditions

Performance Testing Results

Garment Applications

Designed to support diverse garment types with consistent transfer quality

T-Shirts

Cotton, polyester, and blended fabrics

Hoodies

Heavy-weight garments and fleece materials

Sportswear

Performance fabrics and athletic wear

Blended Fabrics

Cotton-polyester and specialty blends

Application Gallery

Real-world applications demonstrating DTF transfer film performance across different garment types and fabric compositions.

OEM & Custom Film Solutions

OEM development based on real production conditions and long-term supply requirements

Film Thickness Adjustment

Customized thickness for specific printing equipment and applications

Coating Formulation Tuning

Optimized coating chemistry for specific ink systems and requirements

Hot Peel / Cold Peel Customization

Tailored peeling behavior to match production workflows

Single-sided or Double-sided Options

Choose the configuration that best fits your printing setup

Roll Width and Length Customization

Custom roll dimensions to optimize material usage and handling

Private Label & Packaging

Custom branding and packaging solutions for distributors

OEM Development Process

Requirements Analysis

Understanding your specific production needs and market requirements

Sample Development

Creating custom samples based on your specifications

Testing & Optimization

Iterative testing and refinement for optimal performance

Production Scale-up

Seamless transition to full-scale manufacturing

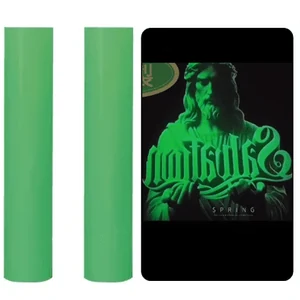

Special Effect DTF Transfer Films

Special effect films are developed based on standard DTF transfer film performance foundations

Glitter

Sparkle effects

Reflective

High visibility

Metallic

Premium finish

Glow-in-the-dark

Luminescent effects

Special Effects Gallery

Explore the creative possibilities with our special effect DTF films

Frequently Asked Questions

Common questions about DTF transfer film applications and performance

What fabrics are compatible with DTF transfer film?

DTF transfer film works on cotton, polyester, cotton-poly blends, nylon, denim, and many other textiles. It is suitable for both light and dark fabrics without pre-treatment.

How do I choose between hot peel and cold peel DTF film?

Hot peel film allows immediate peeling after pressing and improves production speed. Cold peel film requires cooling but offers better detail and stability, especially for fine lines and complex designs.

What is the difference between single-sided and double-sided DTF film?

Single-sided film has coating on one side and is suitable for standard production. Double-sided film includes an anti-static backside coating, which improves feeding stability and reduces powder scattering in high-volume printing.

Is DTF transfer film suitable for dark-colored garments?

Yes. DTF printing uses white ink as a base layer, which ensures strong color opacity and brightness on dark garments without fabric dye interference.

Can DTF transfer film be used for small-batch or custom orders?

Yes. DTF transfer film is ideal for small-batch, on-demand, and personalized orders because it does not require screen setup or plate making.

How does DTF film quality affect wash durability?

High-quality DTF film ensures uniform ink absorption and stable release, which improves ink bonding with hot-melt powder. This results in better stretch resistance and long-lasting wash durability.

What heat press settings are recommended for DTF transfer film?

Typical settings are 150-165°C for 10-15 seconds with medium pressure. Exact parameters may vary depending on fabric type, powder formulation, and film model.

Why does powder stick to unwanted areas on the film?

This is usually caused by static electricity, excessive ink wetness, or high humidity. Using double-sided anti-static film and controlling humidity can significantly reduce this issue.

Can the same DTF film be used with different printers and inks?

Most professional DTF films are compatible with common DTF printers and water-based pigment inks. However, matching film quality with stable ink formulation improves consistency and reduces defects.

How should DTF transfer film be stored?

DTF film should be stored in a dry environment at 20-30°C with relative humidity between 40-60%. Avoid direct sunlight, high humidity, and pressure on the rolls.

Looking for a Reliable DTF Transfer Film Manufacturer for Textile Printing?

Partner with YXCDTF for consistent quality, technical support, and customized film solutions that meet your production requirements. From sample development to full-scale manufacturing, we're here to support your success.

Specialized DTF transfer film manufacturing with global B2B focus