Revolutionary Foil UV DTF Technology

Revolutionary cold foiling and digital metallic transfer solutions — designed for premium packaging, labels, and high-impact brand enhancement.

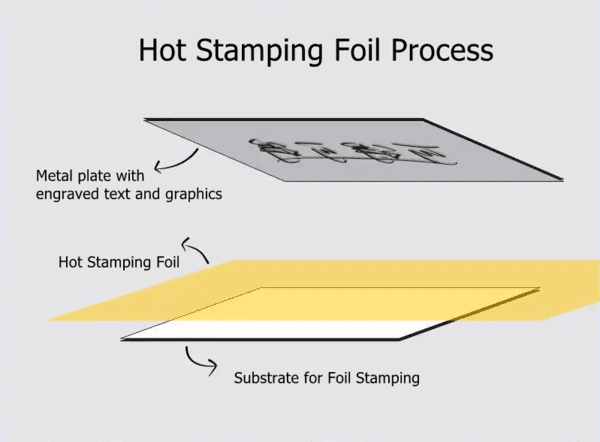

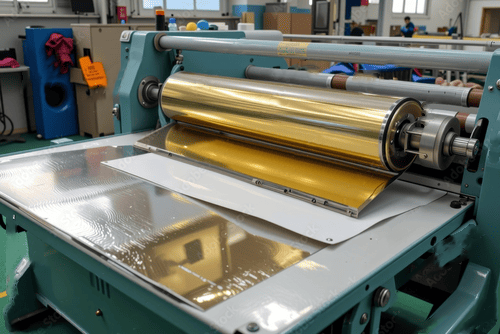

Hot Stamping Process (Thermal Transfer)

For decades, hot stamping has been the standard method for applying metallic finishes on packaging and labels. However, its high temperature, pressure requirements, and limited substrate compatibility often restricted design freedom.So, what is it

Definition & Principle

Hot stamping (thermal transfer) utilizes heat-pressure transfer principles to transfer metallic layers from aluminum foil to substrate surfaces, creating premium metallic visual effects through controlled temperature, pressure, and timing parameters.

Foil Structure Layers

Advantages

- • Strong adhesion and stable application

- • Excellent weather and wear resistance

- • Mature technology for high-volume production

- • Consistent quality and durability

Limitations

- • Requires heating equipment and precise control

- • Limited compatibility with certain substrates

- • Less flexible for small batch production

- • Higher setup costs for tooling changes

Cold Foiling / Digital Cold Foil Technology

Cold Foiling — also known as Digital Cold Foil Technology — is a modern UV-based metallic transfer method that eliminates heat and pressure.This digital, heat-free process works on diverse materials such as paperboard, PET, PVC, glass, and metal, offering faster setup, lower production costs, and greater design flexibility.

UV Adhesive Application

Apply UV-curable adhesive or bonding agent to substrate surface in desired pattern areas

Foil Lamination

Position metallic foil over adhesive areas and apply pressure for proper contact

UV Curing & Release

UV light cures adhesive, foil removal leaves metallic layer only in bonded areas

Key Benefits

No Heat Required

Lower equipment investment and energy consumption

Flexible Production

Quick changeovers ideal for short runs and samples

Enhanced Effects

Gradients, holographic, and specialty finishes

Integration Ready

Seamless workflow with digital printing systems

UV DTF Foil Crystal Label / Cold Foil Technology

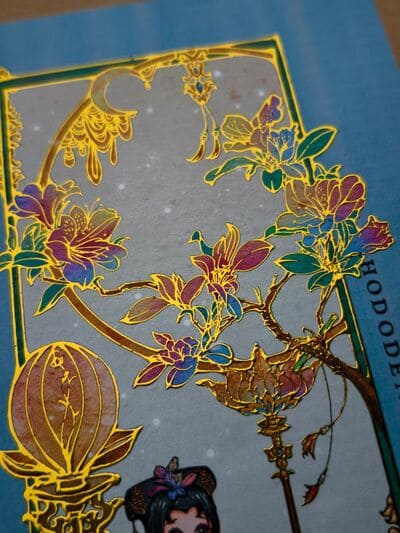

Now a newly revolutionary cold foiling and digital metallic transfer solutions for for premium packaging, labels, and brand enhancement applications borned.UV DTF cold foil transfer isn’t just an upgrade — it’s the future of metallic printing. Let’s explore how it transforms every surface into a statement of luxury.

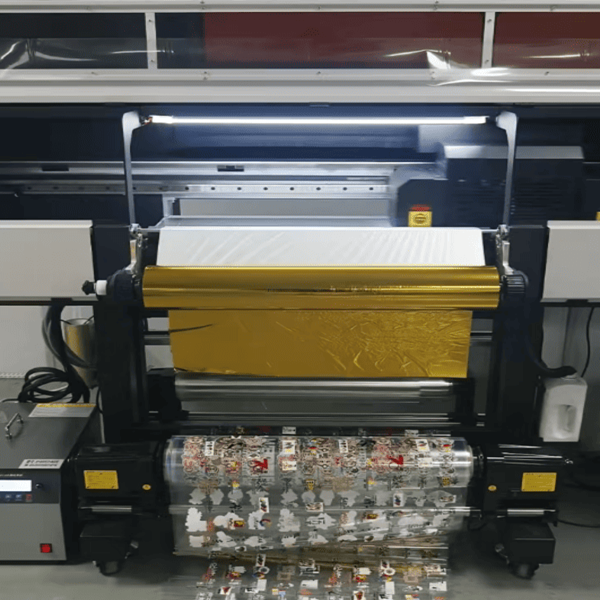

Advanced Manufacturing Process

This process integrates UV DTF Foil All-in-One Printer, UV DTF AB film lamination, and metallic foil paper application into a digital cold transfer workflow.It provides designers and manufacturers with complete freedom — to achieve mirror-like metallic shine, fine text accuracy, and multi-layer texture effects without the complexity of traditional hot stamping.

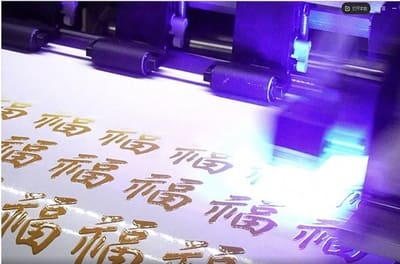

UV DTF A Film Printing

White ink base, pattern layers, and UV Foil ink application on carrier film

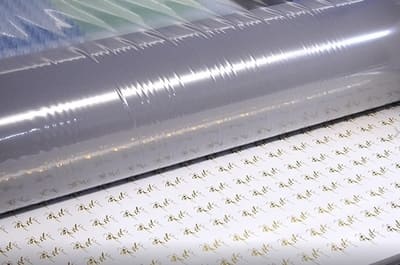

Selective Foil Paper Application

UV adhesive curing and metallic foil transfer to printed a film graphic

UV DTF B-Film Release

Transparent protective layer application for final crystal label completion

Waste-Free A-Film Technology

Pre-Cured Adhesive

UV adhesive pattern printing and controlled pre-curing on A-film

Selective Bonding

Metallic layer bonds only to cured adhesive areas during lamination

Clean Release

Excess foil remains on carrier, eliminating waste removal steps

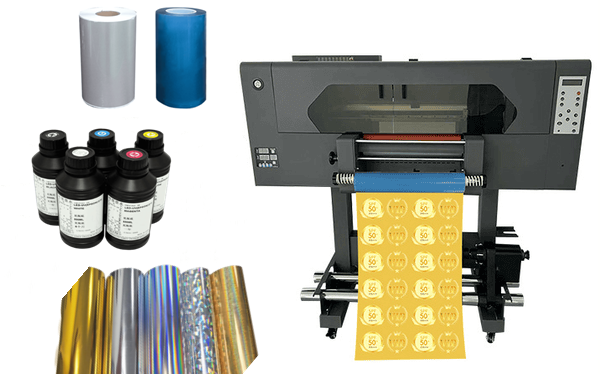

UV DTF Metal Foil Printing Material Kit

Shine Brighter with UV DTF Metal Foil Printing On Various Ojbects You Want

Discover UV DTF metal foil printing with UV A film, transfer films, and foil paper. Achieve premium metallic finishes for packaging, labels, and décor– perfect for luxury packaging, labels, and personalized products..

UV DTF Foil Printing Material Kits

Comprehensive UV DTF foil printing solutions for professional applications with industrial-grade reliability and premium finish quality,you are no need to change the uv dtf printer,uv ink and uv dtf film

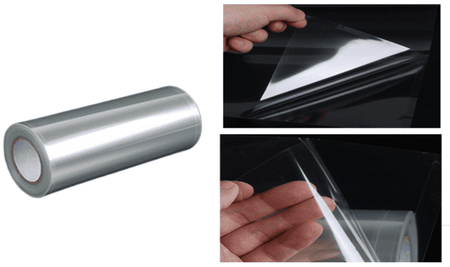

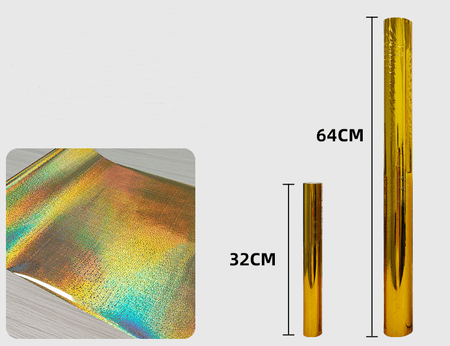

UV DTF PET A Film

- • High-resolution printing capability

- • 7.5c thinkness PET material

- • 32CM/62CM Width Available

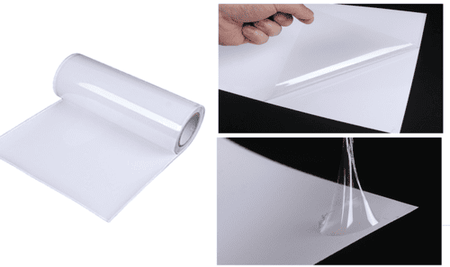

UV DTF Paper A Film

- • 190g double-poly single-silicone release paper

- • Good glossiness

- • Stable release force consistency

UV DTF B Film

- •Easy peeling without damaging

- •Provides consistent transfer efficiency

- •Reduces waste and improves production speed

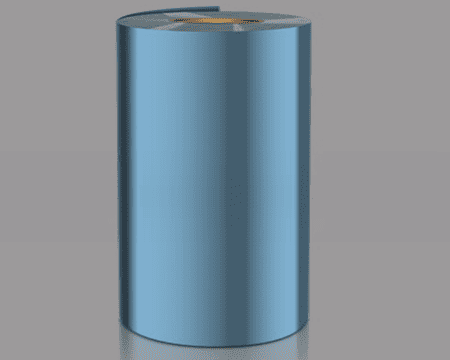

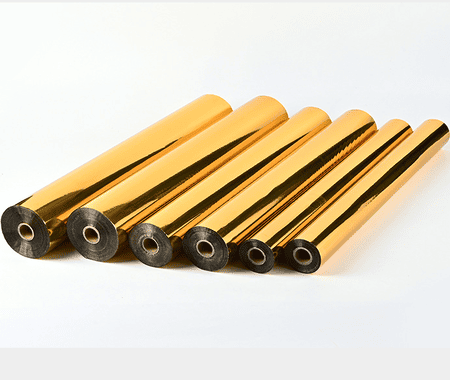

Metallic Foil Paper

- • Brilliant metallic effect for luxury designs

- • Durable and resistant to fading or scratches

- • Wide color options for versatile applications

The Process Of UV DTF Foil Printing

Prepare your artwork with high-resolution design files optimized for UV DTF printing

Cold laminate metallic foil paper onto printed uv dtf a film

After metallic foil layer finish bonding with a film graphic, the uv dtf all-in-one printer then will run the b film onto foil label.

Final the foil uv dtf label done.You can transfer the label onto any hard objects you want.

UV DTF Foil Printing – Make Every Design Shine

Transform your products with premium foil effects that deliver exceptional durability and stunning visual impact

Request Sample

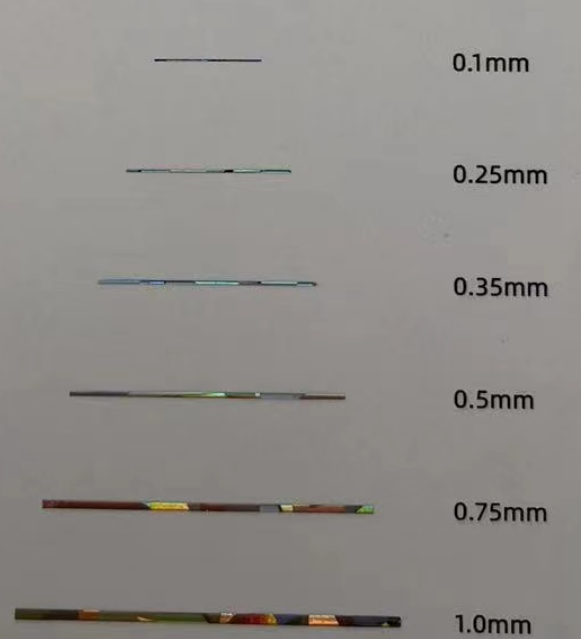

How to Select Premium Foiling Materials

Essential criteria for choosing high-performance metallic foils and adhesive systems,Choosing a high-quality hot stamping paper also plays a key role in UV DTF foil printing

Color Stability & Appearance

- Uniform color distribution without spots or variations

- Consistent mirror finish or desired metallic effect

- Color matching accuracy to approved standards

Adhesion & Durability

- Strong bonding under standard processing conditions

- Excellent fine detail and small text transfer

- Resistance to peeling and delamination

Performance Characteristics

- Scratch and abrasion resistance for daily use

- UV stability and weather resistance

- Chemical compatibility with substrates

Environmental & Safety

- Heavy metal-free and low VOC formulations

- Equipment and operator-friendly processing

- Regulatory compliance and certifications

Material Compatibility Matrix

| Substrate Type | Hot Stamping | Cold Foiling | UV Crystal |

|---|---|---|---|

| Art Paper / Coated Stock | |||

| Synthetic Films | |||

| Transparent Materials | |||

| Textured Surfaces |

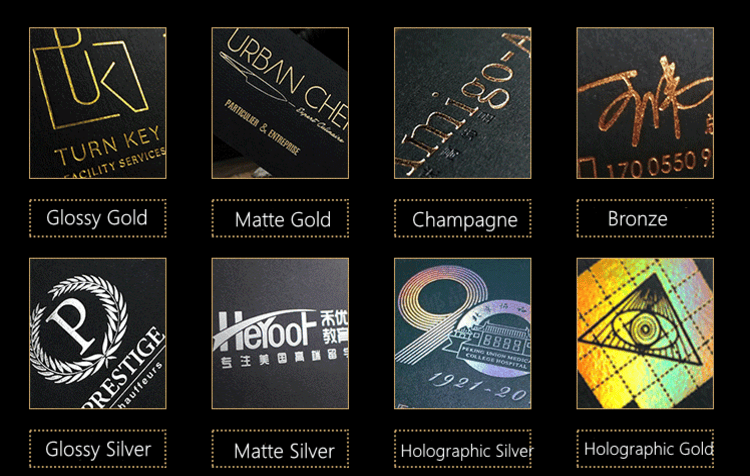

Metallic Foil Paper Color Cards

Classic Metallic Series

Premium metallic foil collection featuring gold, silver, and copper variants

Holographic Metallic Series

Advanced holographic effects with rainbow and prismatic metallic finishes

Troubleshooting & Solutions

Common issues analysis and proven resolution methods for optimal production results

Bubbling / Blistering Issues

Possible Causes

- • Trapped moisture or air

- • Poor substrate breathability

- • Excessive temperature/pressure

Solutions

- • Use staged pressure application

- • Select breathable substrates

- • Optimize temperature/pressure/time

Prevention

- • Pre-condition materials

- • Control environmental humidity

- • Regular equipment calibration

Incomplete Transfer / Missing Foil

Possible Causes

- • Poor foil quality

- • Insufficient adhesive activation

- • Release layer problems

Solutions

- • Upgrade to premium foil materials

- • Optimize UV curing parameters

- • Check adhesive formulation

Prevention

- • Material incoming inspection

- • Process parameter monitoring

- • Regular quality testing

Peeling / Delamination Problems

Possible Causes

- • Surface contamination

- • Mechanical stress

- • Environmental exposure

Solutions

- • Improve surface preparation

- • Apply protective coatings

- • Optimize adhesive selection

Prevention

- • Clean room processing

- • Stress testing protocols

- • Environmental simulation

Poor Detail Definition

Possible Causes

- • Design elements too fine

- • Registration misalignment

- • Pressure distribution issues

Solutions

- • Redesign with larger elements

- • Improve registration systems

- • Optimize pressure parameters

Prevention

- • Follow design guidelines

- • Regular equipment maintenance

- • Process capability studies

Durability & Protection Solutions

Advanced protection methods to extend foil application lifespan and performance,discover our metallic foil paper premium quality.

Protection Methods

UV Protection Coatings

Advanced UV-resistant topcoats prevent degradation from sunlight exposure and maintain metallic brilliance.

Protective Lamination

Transparent films (PET, silicone) provide physical barrier against abrasion and chemical exposure.

Multi-Layer Protection

Combined coating and lamination systems for maximum durability in extreme environments.

Performance Testing Standards

Environmental Resistance Matrix

Temperature

-40°C to +80°C operating range with proper material selection

Humidity

95% RH resistance with moisture barrier protection

UV Exposure

1000+ hours QUV-B testing with minimal degradation

Chemicals

Resistance to common solvents and cleaning agents

Frequently Asked Questions

Expert answers to common questions about foil UV DTF technology

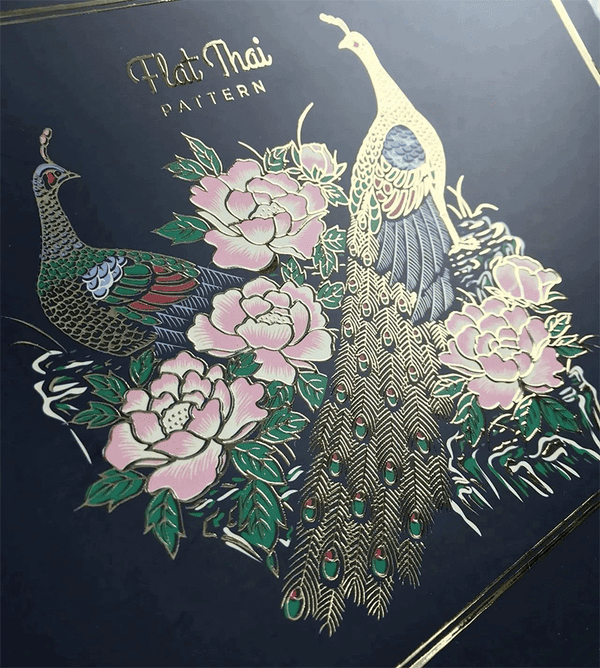

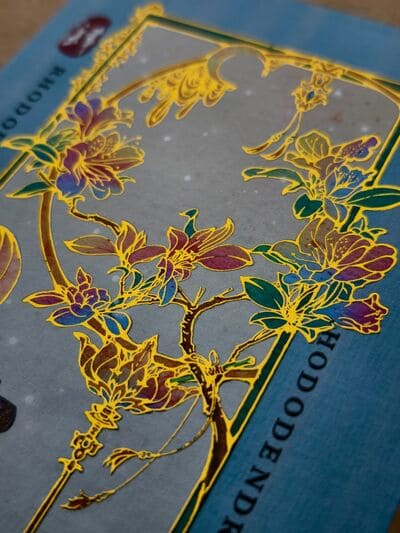

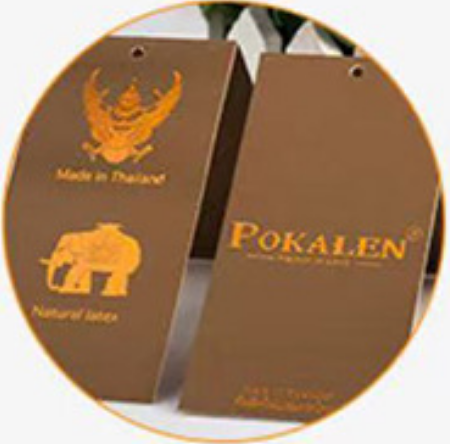

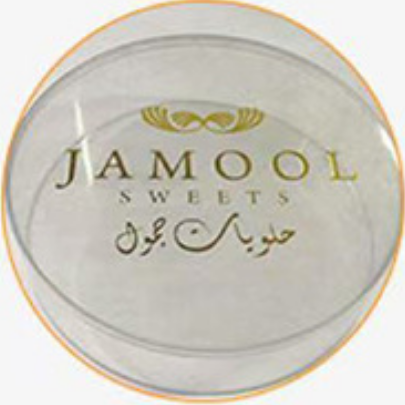

UV DTF Foil Label Application Examples

Real-world applications showcasing the versatility and quality of Foil UV DTF technology — adaptable to a wide range of materials such as wood, glass, plastic, metal, acrylic, and paper. Whether you're a gift brand, label converter, packaging designer, handicraft maker, printing studio, souvenir manufacturer, wholesaler, or importer, you'll find the ideal UV DTF solutions with us for diverse creative and production needs.

Luxury Packaging

Foil UV crystal labels bring a premium, three-dimensional shine and transparent crystal texture to luxury gift boxes. The combination of UV varnish&metallic foiling creates brilliant reflective effect, adding sophistication to brand logos.

DIY Everyday Gifts

Foil UV crystal labels enable creative personalization for everyday items such as glass cups, stationery, and home décor. With simple peel-and-apply operation—they deliver stunning metallic brilliance and high-definition detail..

Holiday & Personal Presents

For holiday seasons and special occasions like Christmas, Valentine's Day, or Chinese New Year, foil UV crystal labels provide a unique way to decorate and customize gifts. Their reflective metallic shine and layered transparency create a festive and artistic look for various themes.

Before & After UV DTF Foil Comparison

Standard UV DTF Printing

Conventional CMYK printing with limited metallic appearance and basic visual impact

Foil UV DTF Enhancement

Premium metallic effects with dimensional quality, enhanced durability, and superior brand impact

Ready to Transform Your Products?

Partner with YXCDTF for cutting-edge foil UV DTF solutions that elevate your brand and exceed customer expectations. Our comprehensive technology portfolio and global support network ensure your success.