Textile UV DTF Solutions

Revolutionary UV-cured direct-to-film technology designed specifically for textile applications. Delivering exceptional durability, vibrant colors, and industrial-grade performance for professional B2B markets.

Why Choose UV DTF for Textiles?

Advanced UV-cured technology delivers superior performance characteristics specifically engineered for textile applications

Instant Cure

UV-cured technology eliminates drying time, enabling immediate handling and faster production cycles

Superior Durability

Enhanced wash resistance and color fastness exceed traditional DTF solutions by 40%

Vibrant Colors

Advanced UV ink formulation delivers exceptional color gamut and opacity on all textile types

Eco-Friendly

Low-emission UV curing process reduces environmental impact while maintaining industrial performance

What Is 3D UV Textile Printing Solutions?

3D UV Printing uses UV flatbed technology to print on flexible TPU or PU vinyl instead of directly on fabrics. The printed vinyl is then heat-transferred to textiles, forming a durable, adhesive, and flexible layer with a 3D effect and scratch resistance

UV DTF Printing Systems

Our company offers 3D textile UV printing vinyl in twomaterials: PU (Polyurethane) and TPU (Thermoplastic Polyurethane). These materials are specifically engineered to meet diverse logo application requirements across multiple product categories, including bags, footwear, headwear, and athletic apparel.

Textile 3D UV DTF Consumables

Specially formulated textile UV inks, various thcken tpu htv or pu htv, and uv printer,cutting machine,all these whole kits optimized for textile applications. Engineered to deliver consistent results across cotton, polyester, blends, and technical fabrics.

UV Textile Ink

Soft, crack-resistant, and highly weatherproof

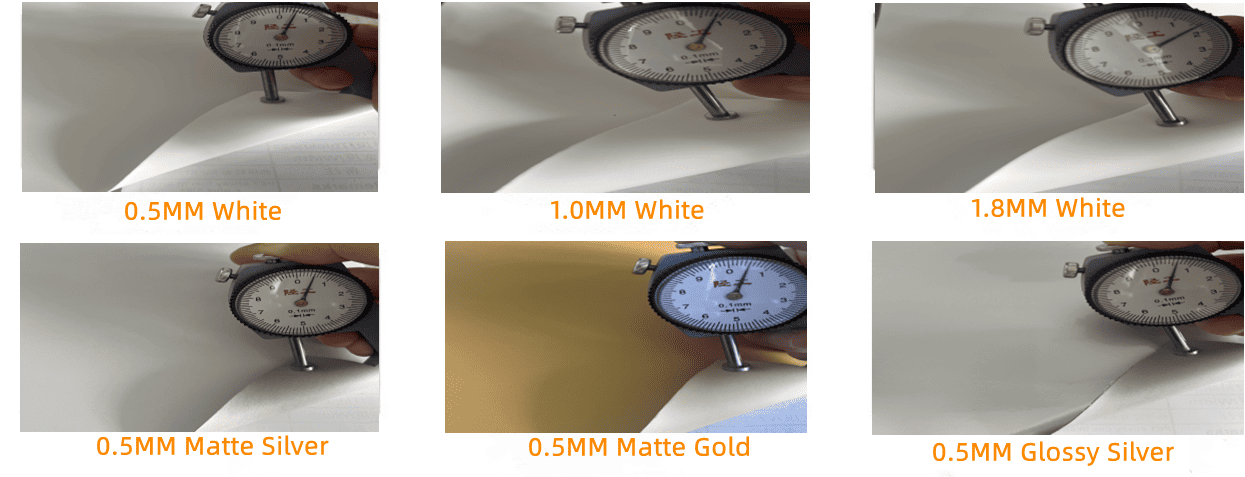

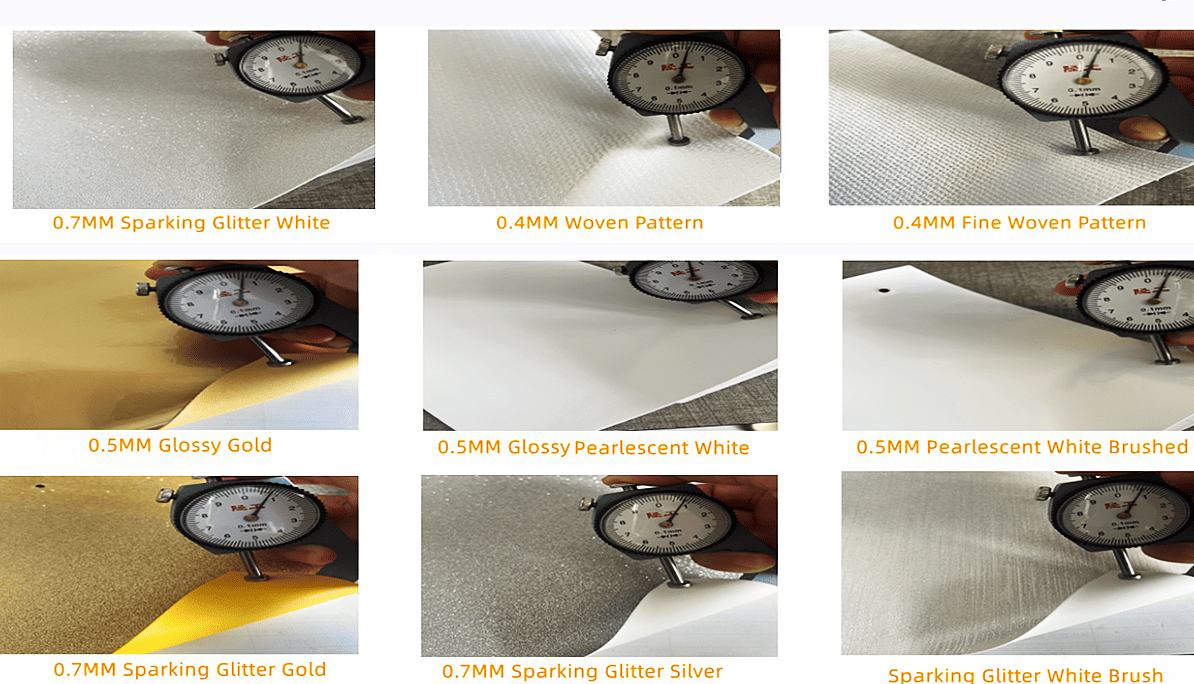

High Density Printable HTV

Available in various colors and textures

Company UV Printer

Just replace ink&material then ideal for common UV printers.

Offer Customized Service

Color, texture, and size can be customized

3D UV HTV On Textile Applications

Versatile UV DTF technology suitable for diverse textile manufacturing requirements

On Apparel Application

3D UV Printing HTV adds a tactile, embossed effect to apparel, making logos and graphics stand out with vivid depth and detail. Ideal for T-shirts, hoodies, and sportswear, it delivers bright colors and lasting flexibility even after repeated washing.

On Bags Application

3D UV Printing HTV patches add texture, depth, and durability to bag designs. They adhere perfectly to various bag materials such as PU leather, nylon, and canvas, delivering a premium embossed appearance with photo-realistic graphics.

On Shoes Application

3D UV HTV provides a flexible, crack-resistant decoration method for shoes. It enables vivid 3D graphics, fine logo details, and customized effects without affecting shoe comfort or breathability.

Ready to Transform Your Textile Production?

Partner with YXCDTF for cutting-edge UV DTF solutions that deliver superior quality, efficiency, and profitability for your textile manufacturing operations.

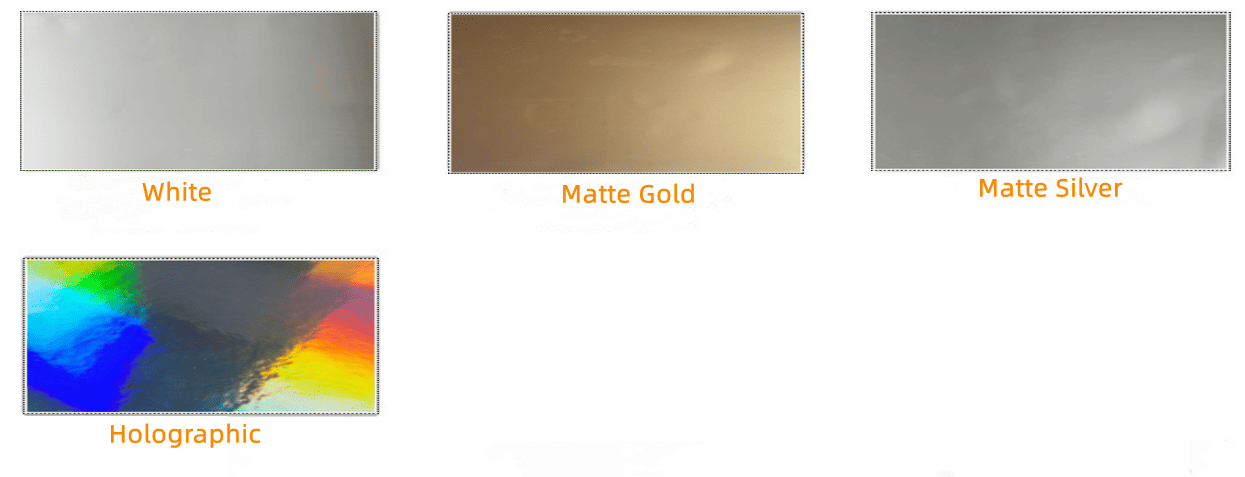

UV HTV Material Color Chart

Explore our comprehensive range of UV HTV materials with vibrant colors and superior durability for professional textile applications

3D UV Printing TPU HTV

3D UV Printing PU HTV

Size Information

Available Roll Widths:

✂ Custom cutting available upon request

Material Properties

Color Matching

Professional color matching services available for custom requirements. Contact our technical team for Pantone color matching.

Request Sample Testing3D UV HTV Printing Process

Master the complete workflow of 3D UV Heat Transfer Vinyl printing with our comprehensive step-by-step process guide. From design preparation to final quality control, achieve professional results with industrial-grade precision and reliability.

Design Preparation

- Create or import your design in vector format (SVG, AI, EPS)

- Set design resolution to 300 DPI minimum for optimal quality

- Mirror the design horizontally for correct transfer orientation

- Adjust colors according to UV HTV color chart specifications

UV Printing Setup

- Load UV HTV material with adhesive side facing up

- Calibrate UV printer for material thickness and type

- Set UV lamp intensity according to material specifications

- Perform test print to verify color accuracy and adhesion

Printing Execution

- Print design with appropriate UV ink coverage

- Ensure complete UV curing during printing process

- Monitor print quality and make real-time adjustments

- Allow material to cool completely before handling

Cutting & Weeding

- Use appropriate cutting blade for UV HTV material

- Set correct cutting pressure to avoid material damage

- Weed excess material carefully using professional tools

- Apply transfer tape for complex multi-part designs

Heat Press Application

- Preheat garment to remove moisture and wrinkles

- Position design accurately using alignment guides

- Apply heat press at 160-180°C for 10-15 seconds

- Use medium pressure for optimal adhesion

Finishing & Quality Check

- Remove carrier film while material is still warm

- Inspect transfer for complete adhesion and quality

- Perform stretch test to verify flexibility

- Package finished product with care instructions

Optimal Temperature

Press Duration

Durability Rating

Frequently Asked Questions

Get answers to common questions about 3D UV DTF textile printing solutions and technical specifications

{$content}

What fabrics are compatible with 3D UV DTF Heat Transfers? ▼

How does 3D UV DTF compare to traditional DTF Film Printing? ▼

What is the minimum order quantity for custom colors? ▼

How should 3D UV DTF HTV be stored? ▼

What's the main difference between PU and TPU vinyl? ▼

Which material is more flexible and durable? ▼

How do they perform under temperature and weather conditions? ▼

Are there differences in surface texture and appearance? ▼

What equipment is needed for 3D Textile UV DTF printing? ▼

Can UV DTF HTV be applied to dark garments? ▼

What is the wash durability of 3D UV DTF Heat Transfer Vinyl? ▼

Do you provide technical training and support? ▼

Which one has better adhesion to fabrics? ▼

Which is more cost-effective? ▼

What are the best applications for each material? ▼

How about environmental stability? ▼

Still Have Questions?

Our technical experts are ready to help you optimize your UV DTF textile printing process and achieve superior results.