3D UV TPU

Garment Film for

Durable Fabric Printing Applications

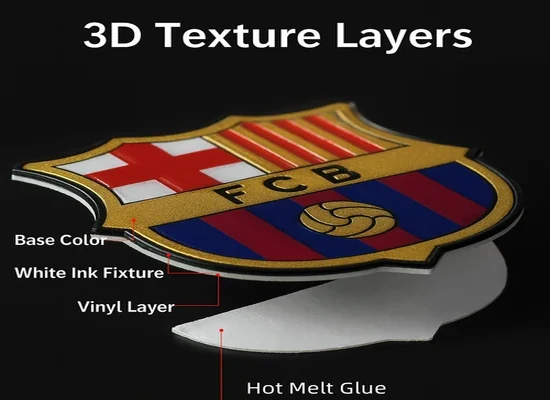

UV printable PU or TPU vinyl types engineered for flexible, durable, and high-impact 3D logos on textile surfaces. Designed for professional garment decoration where strong adhesion, stretchability, and visual impact are essential.

What Is Textile UV DTF Vinyl?

Textile UV DTF vinyl is also commonly referred to as UV DTF Garment Film,it is a specialized UV printable vinyl made from PU or TPU materials, designed for 3D UV printing and heat transfer onto textile fabrics.

Instead of printing directly on garments, UV flatbed printers print high-resolution designs onto flexible vinyl sheets. The printed vinyl is then cut and transferred to fabric using a heat press.

The vinyl layer becomes both the image carrier and a durable, flexible protective layer on the garment surface, delivering strong adhesion, scratch resistance, and a distinctive 3D effect.

PU vs TPU: Which UV DTF Garment Film Is Better

PU-Base UV DTF Film

- Moderate flexibility with semi-rigid feel

- Good abrasion resistance

- Good UV and water resistance

- More economical option

Best for: bags, caps, casual footwear

TPU-Base UV DTF Film

- Excellent flexibility and elasticity

- Superior abrasion and tear resistance

- Excellent UV, water, and oil resistance

- Premium pricing for enhanced performance

Ideal for: sportswear, athletic apparel, and stretch fabrics

Supporting Note: Both PU and TPU UV vinyl are fully compatible with UV printing technology, delivering vivid colors, precise details, and long-lasting logo quality.

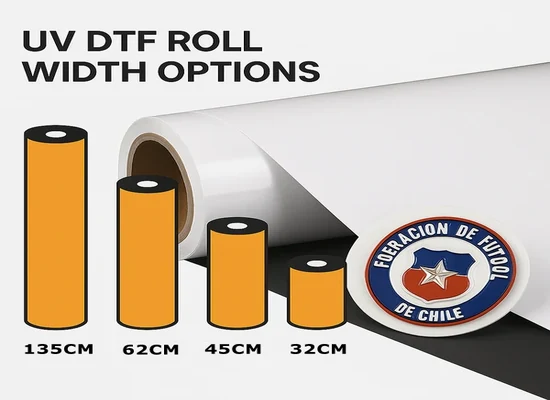

Sizes, Thickness & Color Customization

Popular Width

135 cm (can be slit into 32 cm / 45 cm / 62 cm);Length is 25 or 50 meters

Common Thickness Options

Special Thickness Options

Premium Features

- Textured Surface

- Chameleon Texture

- Special surface: Glitter/Pearl/Brushed

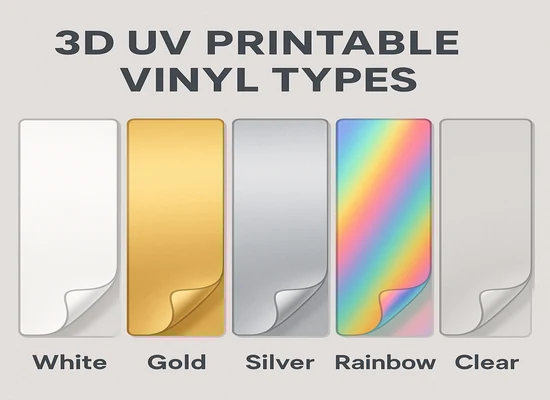

Color Options

- White/ Transparent

- Holographic Silver/Gold Options

- Matte Gold/Silver; Glossy Gold/Silver

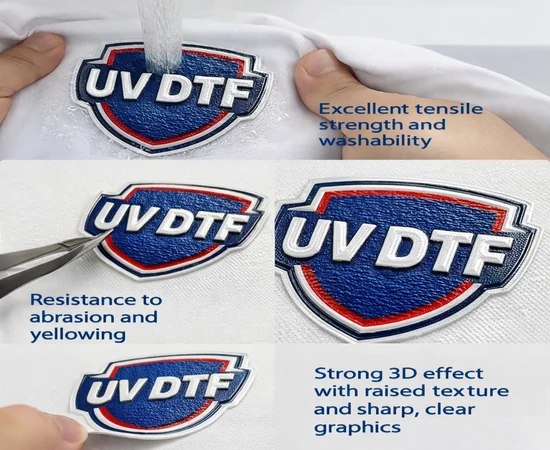

Why Use 3D UV TPU Film for Garment Logos Decoration

High-purity PU / TPU base layer

Ensures strong fabric bonding and reliable adhesion

Excellent raised performance

Creates 3d textured logos and graphics that stand out from the fabric surface

Scratch-resistant surface

Durable surface maintains appearance through heavy use

Multi-fabric compatibility

Maintains adhesion on cotton, polyester, blends, and elastic fabrics

Wash-stable performance

Stable performance under repeated washing cycles

How Does 3D UV DTF TPU Printing Work on Fabric

UV Printing

Print the design directly onto the UV vinyl using a UV flatbed printer.

Cutting

Use a destop cutter or plotter to cut the printed vinyl into logos or shapes.

Heat Transfer

Transfer the vinyl onto fabric using a heat press machine.

Supporting Copy: The TPU hot melt layer ensures excellent wash fastness and adaptability to different textile materials.

What Fabrics Are Compatible with UV DTF TPU Film

Designed to deliver strong adhesion, stretch-friendly performance, and durable 3D logos across a wide range of textile applications.

Compatible Fabrics

Polyester

Excellent adhesion and durability

Cotton & Blends

Strong bonding on natural fibers

Nylon

Reliable performance on synthetic materials

Spandex & Elastic

Superior stretch compatibility

Application Areas

Sportswear and Jerseys

Athletic wear requiring flexibility and durability

Uniforms and Workwear

Professional garments with branding requirements

Streetwear and Fashion

Fashion garments with distinctive 3D effects

Caps, Bags, and Footwear

Accessories requiring durable logo applications

Common Issues in UV DTF Garment Label Production

In real garment production, most failures are not caused by the UV DTF film alone, but by a combination of ink selection, curing conditions, adhesive behavior, heat press parameters, and fabric characteristics. Understanding the real causes is critical for stable production.

Label Cracking After Application

Root Causes

- • Ink formulation lacks flexibility

- • Insufficient UV curing energy

- • Over-curing causing brittleness

Solutions

- • Optimize UV curing parameters

- • Use flexible UV ink formulations

- • Test cure depth vs flexibility balance

Poor Adhesion After Heat Press

Root Causes

- • Hot melt adhesive performance issues

- • Incorrect temperature settings

- • Insufficient pressure or dwell time

Solutions

- • Calibrate heat press temperature

- • Adjust pressure and timing parameters

- • Test adhesive activation temperature

Cracking or Peeling After Washing

Root Causes

- • Incomplete bonding during heat transfer

- • Fabric incompatibility issues

- • Coated or low-energy textile surfaces

Solutions

- • Pre-test fabric compatibility

- • Ensure complete heat transfer bonding

- • Consider fabric pre-treatment methods

Film Curling During Printing or UV Curing

Root Causes

- • Material stability issue of film itself

- • Poor thermal resistance under UV curing

- • Affects printing accuracy and layer alignment

Solutions

- • Replace film supplier immediately

- • Source thermally stable UV DTF films

- • Test film stability before production

Critical Issue: This is a fundamental film quality problem that requires immediate supplier change.

Cracking on High-Stretch Fabrics

Technical Limitation

- • UV DTF not ideal for extreme stretch fabrics

- • Elasticity exceeds UV-cured layer tolerance

- • Mechanical stress causes inevitable cracking

Recommendations

- • Consider alternative decoration methods

- • Use traditional DTF for high-stretch applications

- • Test stretch limits before production

Application Limitation: This is not a film defect but a technology limitation for specific fabric types.

Need Technical Support?

Our technical team provides practical troubleshooting support based on real production experience. Get expert guidance for stable UV DTF production.

Is 3D UV DTF Garment Film Suitable for

Large-Scale Production Compared With Screen Printing Labels?

When evaluating decoration methods for garments, UV DTF garment labels and traditional screen printing labels serve different production needs, but UV DTF offers clear advantages in flexibility, speed, and sustainability.

No Screen Setup, Faster Turnaround

Unlike screen printing, UV DTF does not require screen preparation or plate making. This significantly reduces setup time, making it ideal not only for small orders and fast turnaround, but also for high-efficiency production with frequent design changes.

Efficiency for Both Small and Large Batches

UV DTF garment film supports scalable production. Once printing parameters are stabilized, it can be used for continuous runs without the downtime associated with screen changes, improving overall workflow efficiency.

Lower Setup Cost and Less Waste

Screen printing involves higher initial setup costs and ink waste during setup and cleaning. UV DTF minimizes material waste, making it more cost-effective for diversified orders and short-to-medium production cycles.

Environmental Advantages

UV DTF printing consumes less water and produces less chemical waste compared to traditional screen printing. This makes it a more environmentally friendly solution for garment manufacturers facing increasing sustainability requirements.

Ideal Use Scenarios

UV DTF garment labels are especially suitable for:

Small to Medium Batch Production

Optimal for flexible production volumes

Fast Reorders and Customized Designs

Quick adaptation to design changes

Brands Requiring Short Lead Times

Rapid market response capability

Factories Looking to Reduce Setup Complexity

Streamlined production workflow

Soccer Garment Logos & Hat Logos

The 3d uv textured patches are perfect for sports apparel decoration and promotional items

Who Should Use 3D UV DTF Vinyl

3D UV DTF vinyl is designed for customers who need raised texture, strong visual impact, and flexible production for logos and patches across garments and textile-related products.

Brand Companies & Factories

Used for creating 3D TPU patches, UV patches, and raised logos on garments, bags, hats and accessories. Ideal for premium branding, fast sampling, and flexible production without screen setup.

Logo & Patch Manufacturers

Suitable for workshops producing custom logo patches,heat transfer logos and PVC rubber labels, especially for small batches and quick turnaround orders.

Embroidery & Badge Factories

Adopted as a complementary solution to embroidery for producing 3D UV textured patches, TPU-based raised patches, and hybrid embroidery + UV designs, including automotive and industrial badges.

Screen Printing Logos Producers

Used as a screen-free alternative for silicone heat transfer labels, reducing setup time and enabling frequent design changes compared to traditional screen printing.

Importers & Distributors

Suppliers for OEM and wholesale markets, covering materials and printer selling kits and custom heat transfer logos printing services across different regions.

This solution is ideal for manufacturers and brands looking to expand patch and logo production with higher efficiency and design flexibility.

Why Choose YXCDTF

We are not just a material supplier -- we are a manufacturer with long-term expertise in heat transfer lamination and hot-melt adhesive technology, supporting garment and patch production at scale.

15+ Years Experience

Proven Manufacturing Expertise

Two decades of specialized experience in heat transfer lamination and hot-melt adhesive technology, delivering consistent quality for professional applications.

Rapid Development

Fast Market Response

Advanced texture development capabilities enabling fast sampling and seasonal product launches to keep pace with market demands.

Stable Production

1,000+ sqm/day Capacity

Consistent high-volume production capability with short lead times, ensuring reliable supply for large-scale operations.

Custom Solutions

Tailored Applications

Custom material solutions available for different applications, ensuring optimal performance for your specific production requirements.

Ready to Scale Your Production?

Partner with a manufacturer that understands the technical demands of professional heat transfer applications.

Advantages of YXCDTF Textile UV DTF Vinyl

High-purity TPU / PU base layer

Premium raw materials ensure consistent performance and reliability

Superior bonding on stretch fabrics

Engineered specifically for elastic and performance textiles

No cracking, lifting, or edge curling

Advanced formulation prevents common failure modes

Excellent wash resistance (50+ wash cycles)

Maintains appearance and adhesion through repeated laundering

Stable performance for heavy-use garments

Designed for demanding applications and frequent wear

Frequently Asked Questions

Common questions about textile UV DTF vinyl performance and applications

Basics & Applications

Is textile UV DTF vinyl washable?

Yes. Textile UV DTF vinyl offers good wash durability when applied correctly. It resists cracking and fading under normal washing conditions, making it suitable for daily-wear garments.

What fabrics are compatible with UV vinyl?

Textile UV DTF vinyl works on cotton, polyester, cotton-poly blends, and some stretch fabrics. It performs best on smooth textile surfaces with stable heat resistance.

How does UV vinyl compare with traditional HTV?

UV vinyl does not require cutting or weeding like HTV. It allows full-color printing, finer details, and faster production, especially for complex or small-batch designs.

Does UV vinyl crack on stretch fabrics?

High-quality textile UV DTF vinyl maintains flexibility after curing. When matched with the right adhesive layer, it stretches with the fabric and minimizes cracking.

Can UV vinyl be used for sports jerseys?

Yes. UV vinyl is suitable for sports jerseys, training wear, and uniforms. It offers good stretch recovery and strong adhesion when applied under proper heat and pressure.

Is textile UV DTF vinyl suitable for small-batch production?

Yes. UV vinyl is ideal for short runs and customized orders because it supports digital printing without screens, plates, or cutting steps.

Performance & Production

What textures or effects can UV vinyl produce?

Textile UV DTF vinyl can create matte, glossy, embossed, metallic, and 3D textured effects. This makes it suitable for premium branding and decorative applications.

Is UV vinyl safe for skin-contact garments?

Professional textile UV DTF vinyl is designed for garment use and is safe for normal skin contact. For sensitive applications, testing and certification confirmation are recommended.

How does UV curing affect durability?

UV curing creates a stable ink layer with strong surface hardness. Proper curing improves scratch resistance, wash durability, and long-term color stability.

What heat press settings are recommended for textile UV vinyl?

Typical heat press settings range from 140-160°C with medium pressure. Exact parameters depend on fabric type, vinyl thickness, and adhesive formulation.

Can UV vinyl be layered or combined with other transfers?

Yes. UV vinyl can be layered or combined with DTF prints for mixed-effect designs. Proper alignment and curing between layers are critical for adhesion.

How should textile UV DTF vinyl be stored?

UV vinyl should be stored in a cool, dry place at stable temperature and humidity. Avoid direct sunlight, excessive heat, and pressure on rolls to maintain performance.

Looking for a Reliable Textile UV DTF Vinyl Manufacturer?

Partner with YXCDTF for premium textile UV DTF vinyl solutions. Get consistent quality, reliable supply, and dedicated OEM support for your UV printing applications.

Professional textile UV DTF vinyl manufacturing with global B2B focus