UV DTF Solutions

Advanced UV-Cured Direct-to-Film Technology for Industrial Applications

Revolutionary UV DTF technology delivering superior durability, vibrant colors, and enhanced production efficiency for global B2B markets.

What is UV DTF Technology?

UV DTF (Ultraviolet Direct-to-Film) represents the next generation of transfer printing technology. By utilizing UV-curable inks and UV DTF AB films, this innovative process delivers exceptional adhesion, durability, and color vibrancy across a wide range of substrates.

Unlike traditional DTF methods, UV DTF technology enables instant curing through UV light exposure, eliminating the need for heat pressing in many applications while providing superior wash resistance and flexibility.

Instant Curing

UV light activation for immediate processing and handling

Enhanced Durability

Superior wash resistance and long-lasting color retention

Advanced UV-Curing Process

Precision-engineered UV DTF systems delivering consistent results across industrial production environments.

UV DTF Product Series

Comprehensive UV DTF solutions engineered for professional applications and industrial-scale production

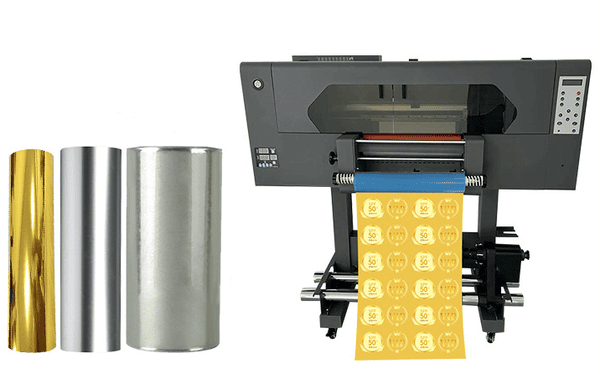

UV DTF Printers

We offer high-Precision UV DTF Printer Solution Of size 30CM/60cm.2400 dpi resolution for exceptionally sharp and detailed prints.Also with Hosan software and i3200 printhead quality grantity.

- High-resolution UV inkjet printing

- Integrated UV curing system

- Automated film handling

UV DTF Ink

Premium UV-curable inks formulated for exceptional adhesion, color gamut, and durability across diverse substrate materials.

- CMYK + White ink systems

- Low-odor, eco-friendly formula

- Superior color reproduction

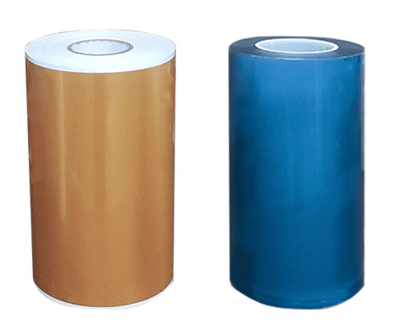

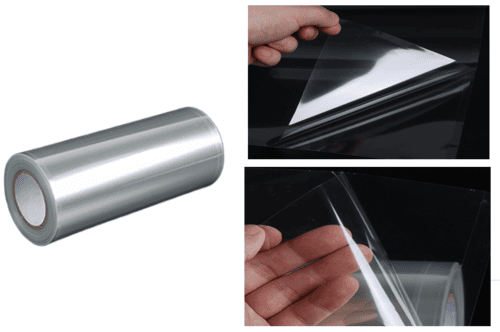

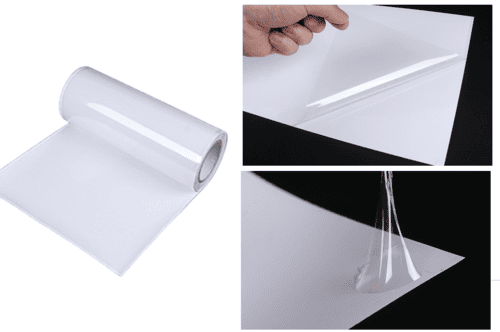

UV DTF AB Film

Specialized transfer films engineered for optimal UV ink reception and superior transfer performance across various applications.

- High-clarity film substrate

- Enhanced adhesion properties

- Clean release technology

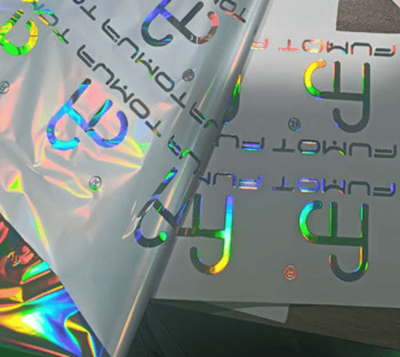

UV DTF Gold A Film

Use the UV DTF Gold A film can be directed to print by printer if you want the label has the metallic golden color. This is the solution you can choose.

- UV Direct-To-Film technology

- Gold Metallic DTF Film

- No need to change uv ink

UV DTF Silver A Film

Use the UV DTF Silver A film can be directed to print by printer if you want the label has the metallic silver color. This is the solution you can choose.

- Multi-substrate compatibility

- Flexible cured properties

- Wash-resistant formulation

Complete UV DTF Systems

Integrated Metallic UV DTF production solutions combining foil,peeling film, and uv printer for turnkey manufacturing operations.

- End-to-end production line

- Automated workflow integration

- Quality control systems

UV DTF Advantages

Superior performance characteristics that set UV DTF technology apart in industrial transfer applications

Instant Processing

UV curing eliminates drying time, enabling immediate handling and processing for enhanced productivity.

Superior Durability

Enhanced wash resistance and color retention compared to traditional DTF methods.

Versatile Application

Compatible with diverse substrates including textiles, plastics, ceramics, and metal surfaces.

Eco-Friendly

Low VOC emissions and energy-efficient UV LED curing systems for sustainable production.

Technical Specifications

Detailed technical parameters and performance characteristics of our UV DTF systems

UV DTF Printer Specifications

UV DTF Ink Properties

UV DTF Applications

Discover UV DTF Film applications on glass, wood, plastic, metal, ceramic, and hard paperboard with durable, vibrant, and versatile decoration solutions

On Glass Object

UV DTF film applies directly to glass surfaces, from windows to glassware, delivering vibrant and durable designs.

- Excellent adhesion on smooth glass

- Waterproof and scratch-resistant

- Ideal for custom décor and signage

On Wood Object

Compatible with finished or painted wood, UV DTF film enhances natural textures with colorful prints.

- Strong bonding even on textured wood

- Crack- and peel-resistant

- Perfect for crafts, furniture, and signs

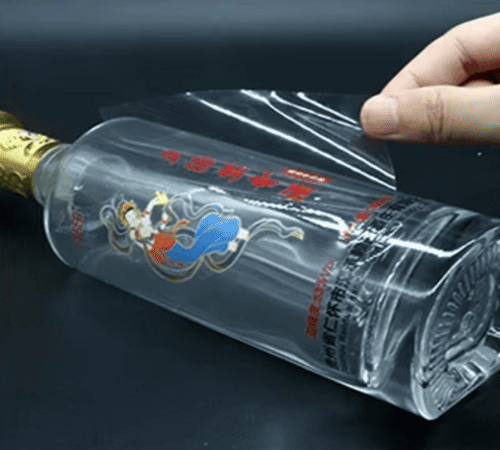

On Plastic Object

Works seamlessly on acrylic, PVC, and other plastics, making it highly versatile.

- Flexible and durable finish

- Bright, clear color reproduction

- Great for bottles, boxes, and packaging

On Metal Object

Adheres to smooth or coated metals, adding long-lasting decoration.

- Excellent wear resistance

- Weatherproof and fade-proof

- Suitable for promotional items and signage

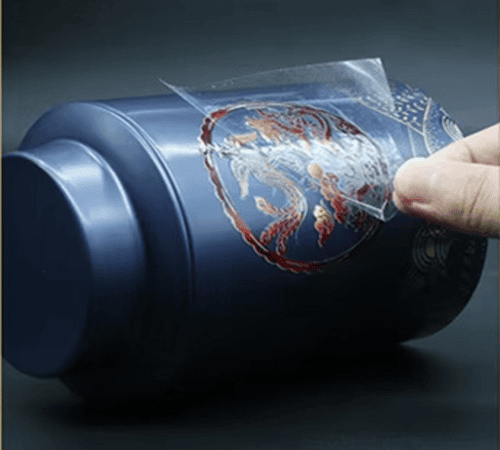

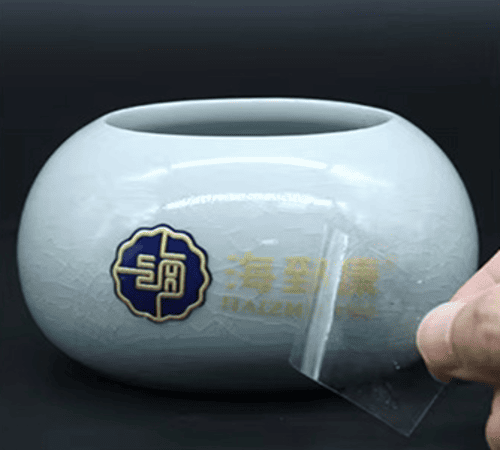

On Ceramic Object

Perfect for mugs, tiles, and plates, UV DTF film creates decorative and practical designs without heat transfer.

- Washable and durable

- Heat and chemical resistant

- Delivers premium-quality finishes

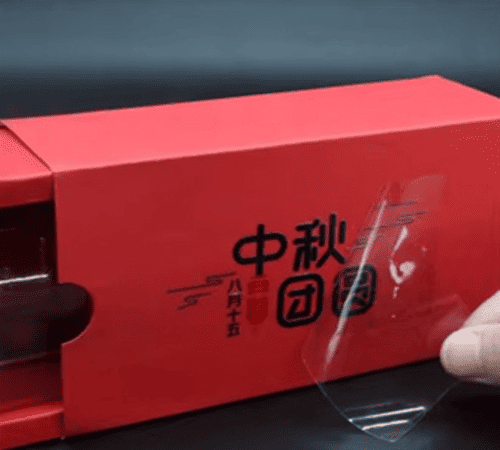

On Hard Paperboard Object

Adds a glossy and professional look to coated or laminated paperboard.

- Lightweight and easy application

- Boosts packaging appeal

- Excellent for gift boxes, labels, and displays

Ready to Implement UV DTF Technology?

Partner with YXCDTF for comprehensive UV DTF solutions tailored to your specific production requirements and market needs.

Our technical experts provide complete support from system selection and installation to training and ongoing maintenance, ensuring optimal performance and ROI for your UV DTF investment.

Technical Consultation

Expert guidance on UV DTF system selection and configuration

Training & Support

Comprehensive operator training and ongoing technical support

Global Service Network

Worldwide service and maintenance support infrastructure

Sample Request Form

UV DTF Metal Foil Printing Solution

Shine Brighter with UV DTF Metal Foil Printing On Various Ojbects You Want

Discover UV DTF metal foil printing with UV A film, transfer films, and foil paper. Achieve premium metallic finishes for packaging, labels, and décor– perfect for luxury packaging, labels, and personalized products..

UV DTF Film Advantages

Discover why our UV DTF films deliver superior performance and reliability for professional applications

Superior Adhesion

Advanced adhesive formulation ensures permanent bonding with diverse substrates, eliminating peeling and edge lifting issues.

Vibrant Color Reproduction

UV-cured ink technology delivers exceptional color saturation, sharp detail resolution, and consistent color matching across production runs.

Wash Durability

Engineered to withstand industrial washing cycles, maintaining color integrity and adhesion through 50+ commercial washes.

Fast Production Speed

Instant UV curing eliminates drying time, enabling immediate handling and finishing for rapid turnaround production schedules.

Flexible Application

Compatible with heat press, conveyor ovens, and automated application systems, adapting to various production workflows.

Cost Efficiency

Reduced waste through precise cutting, minimal setup requirements, and extended shelf life deliver superior cost per unit economics.

Technical Performance Specifications

Maximum Application Temperature

Wash Cycles Durability

UV Curing Time

Color Retention Rate

UV DTF A Film (PET Base)

Professional-grade UV DTF film with PET base construction, engineered for superior performance in industrial printing applications and high-volume production environments.

- Superior durability and longevity

- Excellent chemical resistance

- Premium finish quality

- Industrial applications

UV DTF A Film (Paper Base)

Professional UV DTF transfer film with paper base construction, engineered for high-volume production environments and cost-effective customization solutions.

- Cost-effective solution

- Easy handling and application

- Suitable for short-term use

- High-volume production

PET vs Paper Base Comparison

| Feature | PET Base | Paper Base |

|---|---|---|

| Durability | Excellent | Good |

| Cost Effectiveness | Premium | Economical |

| Application Ease | Professional | Simple |

| Chemical Resistance | High | Limited |

| Best Use Case | Industrial & Long-term | Commercial & Short-term |

Production Excellence

State-of-the-art manufacturing facilities equipped with advanced technology and quality control systems

Advanced Manufacturing Line

Our ISO 9001:2015 certified production facility features cutting-edge coating equipment, precision slitting machines, and automated quality inspection systems ensuring consistent product excellence.

- Automated coating application with ±2% thickness tolerance

- Climate-controlled production environment (±1°C, ±2% RH)

- Real-time quality monitoring with statistical process control

Quality Control Laboratory

In-house testing laboratory equipped with advanced analytical instruments for comprehensive material characterization and performance validation.

- Spectrophotometer color matching and consistency testing

- Tensile strength and elongation analysis

- Thermal stability and aging resistance evaluation

- Adhesion strength testing per ASTM standards

Automated Production Line

High-speed coating and slitting operations with integrated quality monitoring

Testing & Analysis Center

Advanced analytical equipment for comprehensive material characterization

Production Capabilities

m²/day Production Capacity

Continuous Operations

Quality Pass Rate

Lead Time Standard Orders

Quality Assurance Excellence

Our commitment to quality is demonstrated through rigorous testing protocols, international certifications, and continuous improvement processes that ensure every roll meets the highest industry standards.

25+ Years Manufacturing Experience

Quarter-century of expertise in specialty film production and coating technology

ISO 9001:2015 Certified

Internationally recognized quality management system ensuring consistent excellence

REACH & RoHS Compliance

Full compliance with European chemical safety and environmental regulations

OEKO-TEX Standard 100

Textile safety certification ensuring human-ecological safety of textile products

Third-Party Testing Reports

Independent laboratory validation of performance claims and safety standards

Continuous Improvement Program

Ongoing investment in R&D and process optimization for enhanced product performance

Quality Guarantee

Every product batch is backed by comprehensive quality documentation and our commitment to customer satisfaction. We stand behind our products with full technical support and replacement guarantee for any quality-related issues.

Comprehensive Customer Support

Professional support services designed to maximize your success with UV DTF technology implementation

Technical Consultation

Expert guidance on product selection, application parameters, and process optimization for your specific requirements.

Training Programs

Comprehensive training on UV DTF technology, equipment operation, and troubleshooting for your technical team.

24/7 Technical Hotline

Round-the-clock technical support hotline staffed by experienced engineers for immediate problem resolution.

Application Development

Collaborative development of custom applications and specialized solutions for unique market requirements.

Supply Chain Support

Flexible logistics solutions, inventory management, and just-in-time delivery programs for operational efficiency.

Market Intelligence

Regular market updates, trend analysis, and competitive intelligence to support your business growth strategies.

Frequently Asked Questions

Find answers about UV DTF AB Film in our FAQ. Learn how A/B films work, key benefits, surfaces for application, durability, and YXCDTF’s global supply service.

What is UV DTF film and how does it work?

UV DTF film is a special A/B film system used with UV printers and UV-curable inks. Designs are printed on the A film, laminated with B film, and then transferred to hard surfaces with strong adhesion.

What surfaces can UV DTF stickers be applied to?

UV DTF stickers can be applied to glass, plastic, wood, metal, ceramic, acrylic, leather, and other smooth or hard surfaces.

Is UV DTF film waterproof and weather-resistant?

Yes. UV DTF prints are waterproof, scratch-resistant, and UV-resistant, making them suitable for outdoor applications.

Does UV DTF require heat press or special equipment?

No. UV DTF only needs a UV printer, A/B film, and UV inks. After printing and laminating, the sticker can be applied directly by hand without heat pressing.

What are the advantages of UV DTF compared to traditional UV printing?

UV DTF transfers offer easier application, stronger adhesion, and the ability to apply prints on irregular or curved surfaces without needing direct UV printing.

Can UV DTF stickers be removed after application?

UV DTF stickers are designed for strong, permanent adhesion. They are not reusable and may damage the surface if forcibly removed.

Do you offer customized UV DTF film sizes or finishes?

Yes. YXCDTF provides customization in film size, thickness, and surface finishes to meet different production needs.

What is the difference between UV DTF A Film and B Film?

UV DTF A Film is the printable layer where the UV inks are cured, while B Film is the transfer film that carries the design to the final surface, ensuring strong adhesion and easy application.

Ready to Experience UV DTF Excellence?

Request your free sample kit and discover why leading manufacturers choose our UV DTF film solutions for their critical applications.

Complete Sample Kit Includes:

Express Sample Shipping

No Cost Sample Kit

Technical Support Access

Join thousands of satisfied customers worldwide who trust YXCDTF for their UV DTF film requirements. Experience the difference that professional-grade materials make in your production quality and efficiency.