UV DTF AB Film for

Reliable UV DTF Printing

Engineered UV DTF AB film solutions designed for stable adhesion, clear transfer, and consistent performance in commercial UV printing environments.

✔ No glue overflow ✔ High transparency & easy release ✔ Stable performance for mass production

What Is UV DTF AB Film?

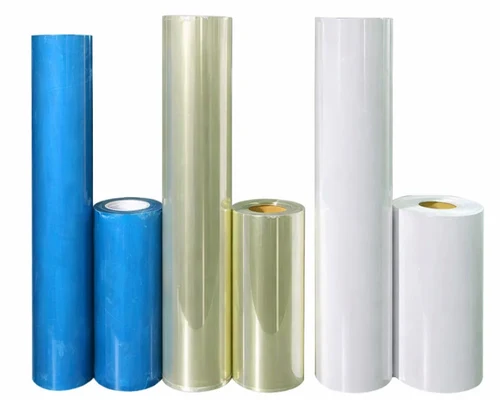

UV DTF AB Film is a two-layer transfer film system used in UV digital printing, consisting of an A Film (printing film) and a B Film (lamination and transfer film).

The A Film receives the UV ink image, while the B Film is laminated onto the printed surface to enable clean transfer and strong adhesion onto various substrates.And uv dtf a film has two types.

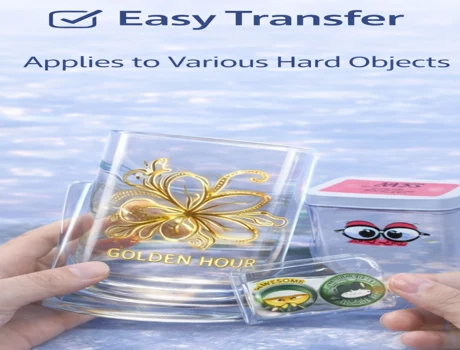

This system allows UV-printed graphics to be transferred without heat, making it suitable for rigid and irregular surfaces.

Core Performance Advantages

Stable Coating Performance

Uniform coating ensures consistent ink acceptance and predictable curing behavior.

Excellent Adhesion Balance

Optimized adhesive layer provides strong bonding without residue or edge lifting.

High Transfer Clarity

Clear film structure supports sharp details, smooth edges, and high visual clarity.

Production-Friendly Handling

Designed for stable feeding, smooth lamination, and efficient transfer in production environments.

UV DTF A Film Options

UV DTF A Film is a core material for UV DTF printing, functioning as the substrate for ink absorption and adhesive application. Two substrate options are available to suit different applications.

PET Base UV DTF A Film

PET-based is a high-temperature-resistant, printable PET film.Its structure consists of a PET base film and a release coating. The PET film layer absorbs the ink, while the release layer enables efficient adhesive transfer.

Learn More

Paper Base UV DTF A Film

It is using wood-pulp base paper as the substrate, with a silicone release coating applied to the surface.And the thickness and physical properties are key factors affecting ink absorption and adhesive transfer performance.

Learn More

Premium UV DTF B Film

It transfers the printed image while carrying the adhesive from the A film to the B film, enabling UV stickers to be applied to rigid surfaces.

Controlled Adhesion

Easy adhesive transfer with no residue.

Clean Release

Zero residue transfer separation

Premium Substrate

10C thickness of pvc materials, make sure transfer easy.

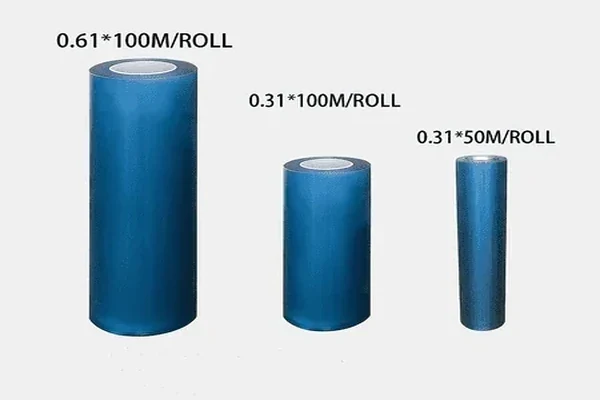

Popular size: 30cm UV Printers use 32cm width, while 60cm printers are compatible with both 32cm and 62cm AB film

UV DTF AB Film Printing Process

UV Printing on A Film

UV ink is printed directly onto the coated surface of the A Film using UV printers.

UV Curing

Printed ink is cured instantly under UV light, forming a durable image layer.

Lamination with B Film

The B Film is laminated onto the cured image to prepare for transfer.

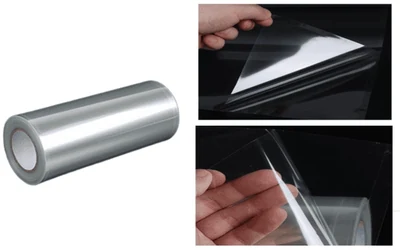

Cold Transfer

The laminated image is transferred onto the target surface using pressure-based cold transfer, ensuring clean edges and strong adhesion.

Application Scenarios

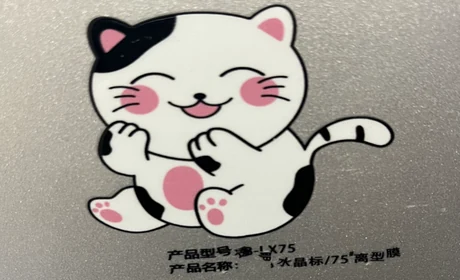

Currently best-selling UV DTF A films use dedicated adhesives with rigid or neutral UV inks, making them suitable for rigid surfaces such as glass, metal, plastic, wood, ceramic, and acrylic, on both flat and curved surfaces.

Glass & Acrylic

Ideal for logos, decorative elements, and signage on smooth rigid surfaces.

Plastic & Packaging

Suitable for customized packaging, containers, and promotional products.

Metal & Industrial Items

Reliable adhesion for metal panels, tools, and industrial branding applications.

You should note that: E.g. ❌Fabric,❌A4 paper, ❌Corrugated cardboard boxes, ❌EVA slippers, ❌kraft packaging etc, the flexible materials like these are required compatible adhesive. Custom UV DTF A film with matched adhesives are available upon request by our company if you need.

Learn More Usage SolutionIssues You May Encounter

Many UV DTF problems are not caused by the printer or ink, but by incorrect AB film selection. The most common issues we see in real production:

Adhesive Overflow on Blank Areas

Adhesive layer too aggressive, poor tack control

Edge Lifting After Transfer

Unstable release layer or ink incompatibility

Small Text Breaking or Distortion

Film tension and coating uniformity not suitable for fine details

Critical Production Risk

These problems often appear after bulk production, not during initial tests -- which leads to rework, delays, and customer complaints. If you meet these issues, you can inquiry our films to test.

Why Choose Our UV DTF AB Film

Not All UV DTF AB Films Work the Same. Although many suppliers label their products as "UV DTF AB Film", the internal coating logic can be completely different.

Our AB Film System Focuses On

Controlled Adhesive Tack

Strong adhesion without glue overflow on empty areas

Stable Release Layer

Clean separation during transfer, even on small text

Ink Compatibility Testing

Verified with rigid and neutral UV DTF ink systems

Batch Consistency

Reduced variation between test samples and mass orders

Quality Positioning

We do not position this as the cheapest option -- it is designed for predictable results.

Production Condition Testing Essential

Testing under your actual production conditions is essential before any bulk order. We recommend comprehensive compatibility testing with your specific equipment, inks, and workflow parameters.

Standardized Quality Control System

Full Performance Testing for UV DTF A Film

The performance of UV DTF A Film must be verified in real applications, not only in laboratory conditions. Based on years of PET film development and real UV DTF production experience, we focus on the most critical performance indicators that directly impact end-use results.

All tests below are designed to reflect real working environments and long-term usage conditions, ensuring stable and reliable performance across different applications.

Transparency & Haze

High transparency with low haze ensures clear visual output and premium surface appearance after application. The surface is smooth and flat, free of defects such as bubbles, wrinkles, or unevenness to make sure good printing.

Abrasion Resistance

Abrasion resistance is evaluated through simulated daily friction to ensure scratch resistance during long-term use. Under the intense friction still keep excellent scratch resistance, and preserve the original smoothness.

Adhesion / Peel Strength

Peel strength is tested according to GB/T 2792-2014, ensuring secure bonding and stable adhesion to various hard substrates. For each bulk batch, a sheet is used to test the adhesive adhesion and peel strength at the center and edges.

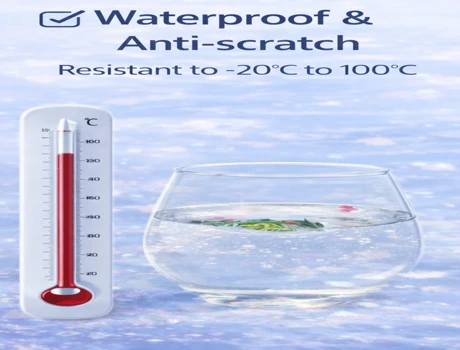

High & Low Temperature Resistance

The film maintains structural integrity and adhesion performance under high and low temperature cycling conditions. At 60-80°C / 80-95% RH condition film structural stability maintained, even −20°C no cracking or embrittlement too.

Why Our Quality Is Stable

Built on Experience, Not Assumptions

Consistent Process, Repeatable Results

Quality stability is achieved through repeatable processes, not individual inspections.

- Standardized raw material selection and PET base film control

- Fixed production parameters and coating consistency

- Defined testing methods with repeatable conditions

- Continuous comparison between test data and application feedback

Every batch follows the same verification logic, allowing performance consistency across long-term supply.

Traceable and Verifiable Quality Control

All key performance tests are:

- Based on recognized testing methods or industry standards

- Conducted using dedicated testing equipment

- Documented for internal traceability and customer reference

This makes our quality control system verifiable, explainable, and trustworthy, rather than subjective or claim-based.

FAQ - UV DTF AB Film Kit

Find answers to the most common questions about our UV DTF AB Film Kit and get the support you need.

What is included in a UV DTF AB Film Kit?

Is UV DTF AB film compatible with all UV printers?

What surfaces can UV DTF AB film be applied to?

What happens if A & B films are not properly matched?

Can I order custom sizes or OEM packaging?

How should UV DTF AB film be stored?

What is the shelf life of UV DTF AB film?

What is the recommended curing method?

Can the film be reused after a failed transfer?

Does the kit include a user guide or support?

Still have questions?

Our technical support team is here to help with your UV DTF AB Film Kit questions.

Looking for a Reliable UV DTF AB Film Manufacturer?

Partner with YXCDTF for stable UV DTF AB film solutions, consistent quality control, and dedicated OEM support for your global printing operations.

Professional UV DTF AB Film Manufacturing & OEM Solutions