UV DTF Paper A Film

Application-Driven Choice for Controlled UV DTF Transfer

Paper-based release film designed for specific UV DTF applications where handling control and stiffness matter more than transfer smoothness.

The Right UV DTF Applications on Transparent Objects

Understanding Paper A Film in UV DTF.Paper A Film is commonly selected for glass, acrylic, and clear plastics,where stable ink laydown and predictable visual results are required.Its stiffness and controlled release characteristics make it suitable for certain manual and creative UV DTF applications.

Best suited for clean, flat visuals on transparent substrates.

Material Structure of Paper A Film

Paper base A Film uses a specially selected paper substrate combined with a functional release coating. The structure provides sufficient mechanical strength for printing and lamination, while maintaining reliable release behavior during UV DTF cold transfer workflows.

Base Material

Double-coated paper (single or double copper paper)

Lamination

Dual-side PE coating

Release Layer

Silicone release coating

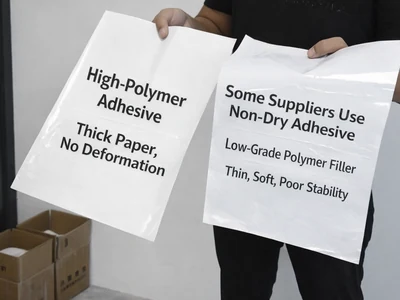

What are the superior characteristics of our Paper A Film?

Designed to support continuous production runs with minimal adjustment and stable output.

Good rigidity and flatness

190 GSM paper base, with thickness, non-deformable

Premium Paper Base

No curling or warping during printing

Reduced Coating Residue

Minimized risk of coating residue on final products

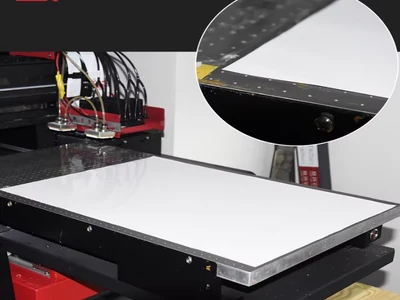

UV DTF Printing Workflow Snapshot

Printing

UV ink is printed directly onto the Paper A Film surface.

Lamination

The printed image is laminated with B Film to prepare for transfer.

Cold Transfer

The image is transferred smoothly without heat, maintaining production efficiency.

Supporting Note: Paper A Film integrates seamlessly into standard UV DTF cold transfer workflows without requiring special adjustments.

Paper A Film vs PET A Film

Application-focused comparison to help you choose the right UV DTF A film for your production needs and workflow requirements.

| Application Aspect |

PET A Film

Professional Grade |

Paper A Film

Creative Grade |

|---|---|---|

|

Transfer Smoothness

Consistency in transfer process |

★★★★★

Excellent

|

★★★★★

Good

|

|

Manual Control

Ease of manual handling |

★★★★★

Moderate

|

★★★★★

Excellent

|

|

Continuous Production

High-volume manufacturing |

★★★★★

Excellent

|

★★★★★

Limited

|

|

Fine-detail Graphics

Precision and detail quality |

★★★★★

Excellent

|

★★★★★

Good

|

|

Creative & DIY Use

Small batch and custom projects |

★★★★★

Limited

|

★★★★★

Excellent

|

PET A Film - Best For:

- High-volume production environments

- Detailed graphics and professional applications

- Consistent transfer quality requirements

Paper A Film - Best For:

- Manual operation and creative projects

- DIY and small batch applications

- Easy handling and user-friendly workflows

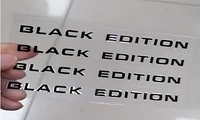

Transfer Behavior Characteristics

Because paper is thicker than PET, you need to be more careful when transferring labels with small lines to ensure they are smoothly applied to objects.

But in application,paper a film have the different features.

Less elastic than PET during transfer

More controlled peeling behavior

Suitable for accurate positioning

When Paper A Film Makes More Sense Than PET

Application Scenarios Where Paper A Film Performs Better

Greeting Cards & Event Decorations

Birthday cards, invitation cards, festive decorations, and customized paper-based products.

Manual Craft & Hobby Projects

Studios, workshops, and hobby applications that rely on manual or semi-manual transfer.

DIY Stickers & Creative Labels

Handmade stickers, decorative labels, and small creative projects.where manual control is important.

Storage & Handling

Environment

Store in a dry, ventilated environment

Conditions

Avoid direct sunlight and excessive humidity

Warehouse

Maintain stable temperature conditions

Supporting Note: Proper storage ensures consistent release behavior and stable production results.

Not Sure Whether UV DTF PET or Paper A Film Fits Your Application?

Request PET & Paper Sample Comparison,both of them are ideal for high-volume production requiring consistent quality and cost efficiency.

Cost-efficient solutions for professional UV DTF production