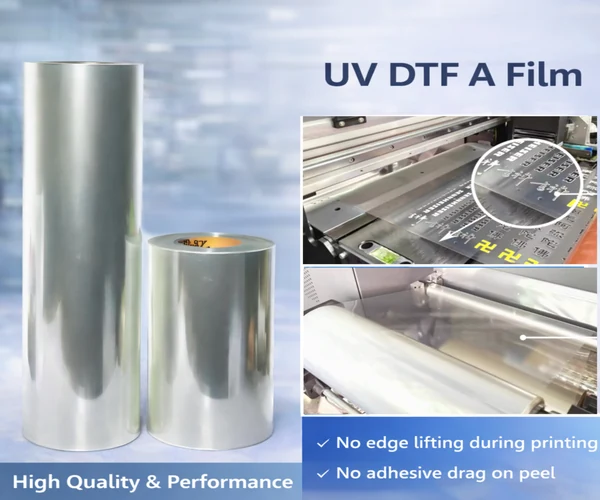

UV DTF

PET A Film

Printable PET base film engineered for controlled UV ink adhesion and clean cold transfer.

PET-based release film engineered to deliver smooth transfer behavior,high dimensional stability, and consistent results in UV DTF workflows.

Key highlights:

✓ PET base with silicone release coating

✓ Smooth and predictable cold transfer

✓ Designed for stable, repeatable production.

In UV DTF printing, the base film is not a carrier.

It defines clarity, stability, and consistency.

PET is chosen not for cost -- but for control.

The Role of PET A Film in UV DTF Printing

PET A Film Controls Stability in UV DTF Transfer

In UV DTF printing, A Film plays a critical role in determining transfer smoothness, image integrity, and production stability.

YXCDTF PET A Film is designed to reduce transfer resistance and minimize deformation, making it suitable for professional and continuous UV DTF production environments.

Transfer Smoothness

Optimized surface properties ensure consistent transfer performance across different substrates

Image Integrity

Maintains sharp details and color accuracy throughout the transfer process

Production Stability

Consistent performance for high-volume manufacturing environments

Adhesive Matching Technology

YXCDTF provides guidance on adhesive matching to ensure clean release and stable UV DTF transfer results. Our UV DTF a film have different glue types.

High Adhesion

This is a general type for hard objects.

Low Adhesion

Suitable for Paper, Cardboard Box

Adhesive for Winter

Its viscosity remains stable even in cold environments.

Designed for cold transfer UV DTF printing.

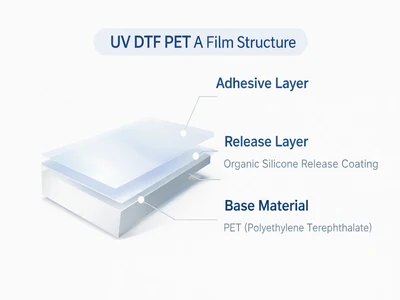

Material Structure & Release Coating Design

Advanced coating technology engineered for optimal UV DTF performance with precise release behavior and chemical stability.

UV DTF PET A Film Structure

Base Material

PET (Polyethylene Terephthalate)

High-strength substrate providing dimensional stability and heat resistance for UV DTF applications.

Release Layer

Organic Silicone Release Coating

Precision-engineered silicone formulation for consistent release performance across temperature ranges.

Coating Control

Double-Side Coating, Controlled Release Behavior

Engineered coating weight and distribution for predictable release force during transfer processes.

Design Intent & Performance

Chemical Inertness

No reaction with UV inks or adhesives, ensuring print quality and transfer integrity throughout the process.

Moisture & Oil Resistant

Advanced barrier properties protecting against environmental factors that could affect transfer performance.

Stable Release Force

Consistent release behavior during cold transfer processes, ensuring reliable production outcomes.

UV DTF Paper A Film vs UV DTF PET A Film

UV DTF PET A Film

Stable, premium production

UV DTF Paper A Film

Cost-sensitive projects

PET A Film is recommended where print quality and production stability are critical.

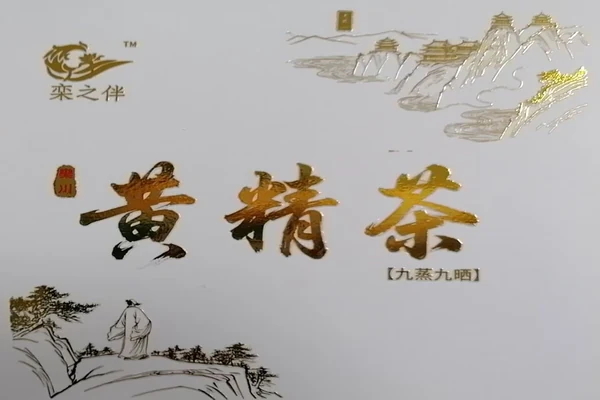

Application Areas Of UV DTF Cold Film

Used in hard surface decoration, branding, labels, and precision UV DTF applications.

Acrylic and Glass Decoration

Perfect clarity for premium glass and acrylic surface applications requiring precise detail reproduction.

Commercial Branding Labels

Brand logos, product identification labels, and professional branding graphics requiring clean edges and consistent appearance.

High-Detail UV Crystal Sticker

Fine lines, small text, and transparent designs where smooth transfer helps preserve detail integrity.

Why Producers Choose PET A Film

PET A Film is selected for production reliability, not for material cost. Our focus is on delivering consistent performance for high-volume manufacturing.

Smoother Transfer Process

Superior transfer performance compared with paper-based A Film, reducing production interruptions and improving workflow efficiency.

Production Reliability

More forgiving in continuous and high-standard production environments, minimizing waste and maintaining consistent output quality.

Better Batch Consistency

Consistent performance across production batches, ensuring predictable results and reducing quality control variables.

Stability Over Manual Control

Designed for stability rather than manual control, enabling automated production processes and reducing operator dependency.

PET vs Paper Base Comparison

PET A Film

- High production reliability

- Consistent batch performance

- Automated process friendly

Paper-Based A Film

- Variable transfer quality

- Requires more manual control

- Batch inconsistencies

Production-Focused Choice

Our PET A Film solutions prioritize manufacturing efficiency and consistent results over material cost considerations.

UV DTF Crystal Label Clear Results

Our PET A Film delivers exceptional optical clarity that translates directly to superior print quality and professional transfer results.

Need a PET A Film Designed for Stable UV DTF Production?

Get consistent quality, reliable performance, and dedicated technical support for your UV DTF printing operations.

Professional PET A Film manufacturing with consistent quality and reliable supply