UV DTF Printing Solution

for Professional Hard Surface Decoration

A reliable UV DTF printing workflow designed for stable production, strong adhesion, and consistent quality on hard surfaces. Built for professional printers, distributors, and brand owners.

Understanding UV DTF Printing

UV DTF (Direct to Film) printing is a specialized digital printing process that transfers UV-cured ink designs from film to hard surfaces with superior adhesion and durability.

How UV DTF Differs from Traditional Methods

vs. Traditional DTF

UV DTF uses UV-curable inks instead of plastisol, enabling direct application to hard surfaces without heat pressing

vs. Screen Printing

Digital process eliminates setup costs, enables complex designs, and supports variable data printing

Production Advantages

Faster turnaround, lower minimum quantities, and consistent quality across production runs

Typical UV DTF Applications

Signage & Displays

Retail displays, promotional signage, exhibition graphics

Packaging & Labels

Product packaging, industrial labels, compliance marking

Promotional Items

Corporate gifts, branded merchandise, custom decorations

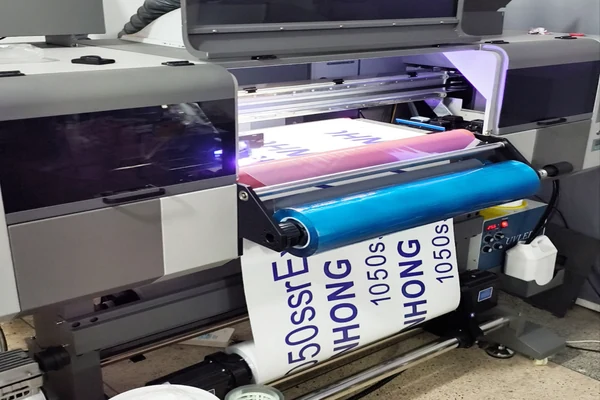

Complete UV DTF Process

Understanding each step ensures consistent results and optimal production efficiency

RIP Setup & UV Ink Printing

- Configure RIP software for UV DTF profile

- Print design on A film using UV-curable inks

- Ensure proper ink density and color accuracy

UV Curing & Adhesive Application

- UV LED curing to solidify printed design

- Apply B film (adhesive layer) over cured print

- Laminate to create transfer-ready AB film kit

Transfer & Adhesion

- Position AB film kit on target hard surface

- Apply pressure for proper adhesion

- Remove A film, leaving design on surface

Film Quality Determines Success

Understanding material compatibility and film behavior is critical for consistent UV DTF production results

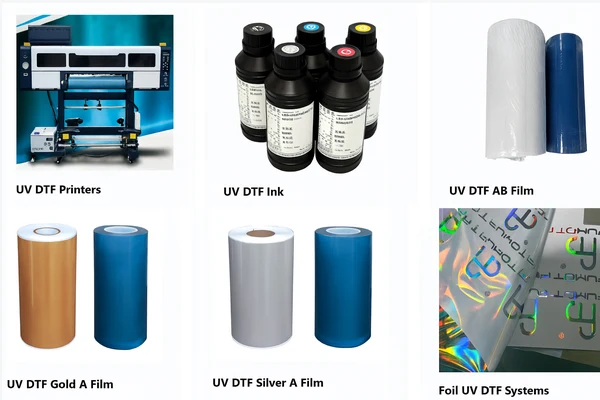

UV DTF AB Film Systems

A Film (Carrier Film)

- Receives UV ink and provides release surface

- Available in PET or paper base materials

B Film (Adhesive Film)

- Provides adhesion to hard surfaces

- Transparent for clear design visibility

PET A Film vs Paper A Film

PET Base A Film

- Superior dimensional stability

- Excellent ink adhesion

- Consistent release behavior

- Higher material cost

Paper Base A Film

- Cost-effective solution

- Environmentally friendly

- Sensitive to humidity

- Requires careful handling

How Film Quality Affects Production

Unstable Films

Inconsistent release, poor adhesion, production waste

Quality Issues

Coating defects, dimensional variations, batch inconsistency

Premium Films

Consistent quality, higher yield rates, predictable results

Quality Control at Every Step

Our manufacturing approach ensures consistent film performance across production batches for reliable B2B partnerships

Manufacturing Standards

Raw Material Control

Certified base films, controlled coating formulations, consistent material sourcing

Coating Uniformity

Precision coating equipment, thickness monitoring, surface quality inspection

Batch Consistency

Statistical process control, batch tracking, performance validation testing

ISO Certified

Manufacturing quality standards

REACH Compliant

European chemical safety

OEKO-TEX

Textile safety standards

Global Export

50+ countries served

Related UV DTF Technical Articles

Deepen your understanding of UV DTF printing technology and best practices

UV DTF vs DTF Printing: Which Is the Right Choice for Apparel and Branding Production?

DTF printing and UV DTF printing are often discussed together, yet they serve different production needs. For apparel manufacturers, printers, and distributors, understanding the real…

3D UV DTF vs Traditional 3D Heat Transfer Patches: Process, Efficiency, and Future Trends

Raised logos and three-dimensional branding elements are widely used in modern apparel and accessories. From sports jerseys and workwear to T-shirts, bags, caps, and footwear,…

How Does Textile UV DTF Vinyl Work on T-Shirts and Sportswear?

For professional apparel printers and manufacturers, decoration methods are evaluated not only by visual results, but also by production efficiency, process stability, and long-term durability.…

DTF Transfer Film Explained: How It Is Used in Garment Printing?

In DTF garment printing, transfer film is often treated as a low-cost consumable rather than a functional component. This misconception is one of the primary…

Hard Surface Applications

UV DTF printing delivers exceptional durability and visual clarity across diverse hard surface applications

Signage & Displays

- Retail point-of-sale displays

- Exhibition graphics and banners

- Directional and safety signage

Packaging & Labels

- Product packaging decoration

- Industrial identification labels

- Compliance and safety marking

Promotional Items

- Corporate gifts and awards

- Branded merchandise decoration

- Custom decorative elements

Performance Characteristics

Superior Durability

UV-cured inks provide excellent weather resistance and long-lasting color retention

Visual Clarity

High-resolution printing with vibrant colors and sharp detail reproduction

Strong Adhesion

Reliable bonding to various hard surfaces without additional adhesives

Looking for a Stable

UV DTF Printing Solution?

Partner with YXCDTF for consistent film quality, technical expertise, and reliable supply chain support. Built for professional printing operations and B2B partnerships.

Why Choose YXCDTF

Specialized Manufacturing

Film manufacturing focus, not general trading

Technical Support

Application guidance and troubleshooting expertise

Global B2B Focus

Designed for distributors and professional printers

Ready to optimize your UV DTF printing workflow?