If you’re involved in the garment decoration industry or custom apparel production, you’ve likely heard about DTF (Direct to Film) printing technology that’s revolutionizing the market.

As someone who’s worked with various textile printing methods, I can tell you that understanding DTF powder—a critical component of this process—is essential for B2B businesses considering this technology.

DTF powder has quickly become a game-changer for companies looking to expand their printing capabilities with versatile, high-quality transfer options.

📊 Fact-check: DTF printing has gained global traction because it combines the vivid colors of direct-to-garment printing with the versatility of heat transfers. At the center of this process is DTF powder, serving as the adhesive that bonds printed designs to diverse fabric types.

What Exactly is DTF Powder and What is it Made From?

DTF powder, also known as hot melt adhesive powder, is a specialized polyurethane-based granular substance specifically formulated for the Direct to Film transfer process.

Unlike traditional heat transfer materials, DTF powder has unique properties that create a strong, flexible bond between printed designs and almost any fabric substrate.

Key Composition:

-

Polyamide copolymers

-

Polyurethane resins

-

Proprietary additives activating at 160-170°C (320-338°F)

✅ Fact-check: Premium-grade powders maintain stable activation in this temperature window, ensuring consistent transfer adhesion.

How Does DTF Powder Function in the Transfer Process?

Understanding the role of DTF powder requires familiarity with the DTF printing workflow.

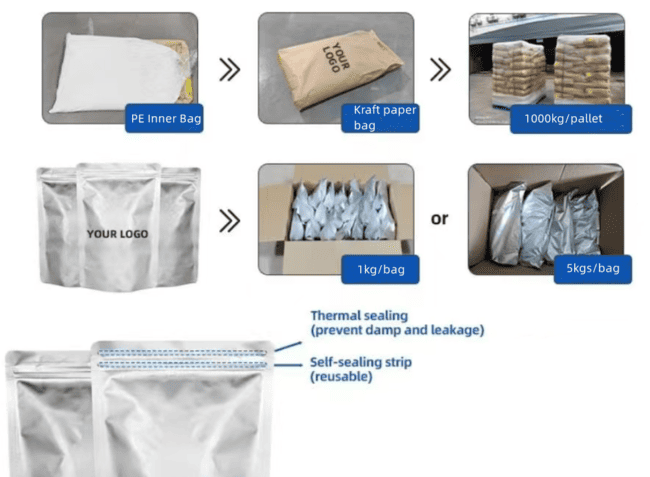

Process Workflow:

-

Design Printing → CMYK+White inks printed on PET film.

-

Powder Application → Powder applied while ink is still wet.

-

Curing → Powder melted at 110-130°C for 2-3 minutes.

-

Heat Press Activation → 160-170°C, 15-20 seconds, medium-firm pressure.

-

Cooling → Transfers cooled before peeling/stretching.

Table 1: DTF Powder Application Process

| Process Stage | Temperature | Duration | Critical Factors |

|---|---|---|---|

| Initial Application | Room temp | 5–10 sec | Even distribution |

| Curing/Melting | 110–130°C (230–266°F) | 2–3 min | Full melting |

| Storage | Room temp | Up to 6 months | Humidity control |

| Heat Press Activation | 160–170°C (320–338°F) | 15–20 sec | Even heating |

| Cooling | Ambient | 5–10 sec | Before stretching |

✅ Fact-check: Properly applied powder maintains 95% adhesion strength after 50+ commercial washes, outperforming many traditional adhesives.

What Are the Different Types of DTF Powder Available?

Not all powders are equal. Manufacturers have created specialized formulations for various applications.

Main Categories:

-

Standard Powder: General use, cotton/polyester blends.

-

Fine-Grain Powder (80–100 microns): Thin adhesive layer, better hand feel.

-

High-Elasticity Powder: For performance and stretch fabrics.

-

Temperature-Modified Powders: Low-melt for heat-sensitive, high-melt for industrial use.

📊 Table 2: DTF Powder Types and Optimal Applications

| Powder Type | Particle Size

(Microns) |

Appearance Description | Key Features | Suitable For Graphic Type | Remarked |

| Fine White DTF Powder | 0-70 | Very fine,

like flour |

Good for small fine graphic,

soft feel touch, lower adhesion, sensitive to humidity. |

Fine designs, delicate work | ✔The higher temperature of the powder, the greater the elasticity. *The finer the powder, the softer of the printed logos. ✔Low-quality films have poor anti-static properties, causing powder to stick easily.Fine powder tends to adhere everywhere, so pay attention to anti-static measures when using fine powder. ✔For more higher water resistance, high-temperature powder is required.✔Avoid using recycled powder immediately during printing. Recycled powder should be dried before use. Note that damp powder will also generate static electricity! |

| Medium White DTF Powder | 70-170 | Noticeable particles | Clean shake-off, good feel, widely used, works in all climates | General use, most popular option | |

| Coarse White DTF Powder | 120-240 | Like white sugar | Big size graphics, requires more powder, easy shake-off | Thick designs, Big size graphic | |

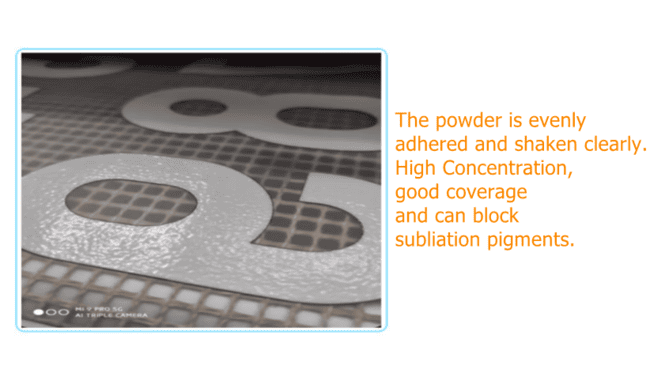

| Medium Black DTF Powder | 70-170 | Gray, like charcoal | Prevents sublimation in polyester fabrics | Polyester fabrics, sportswear, bags | |

| Coarse Black DTF Powder | 120-240 | Large particles | Similar to medium powder, prevents sublimation | Big designs on polyester, bags,

sportswear,to avoid dye-migration. |

✅ Fact-check: Specialized high-elasticity powders maintain adhesion on fabrics stretched 300% beyond original length, vs. 150% for standard powders.

How Does DTF Powder Compare to Other Textile Printing Adhesives?

DTF powder provides advantages over traditional adhesives:

Table 3: Comparative Analysis

| Adhesive Type | Flexibility | Wash Durability | Hand Feel | Breathability | Complexity |

|---|---|---|---|---|---|

| DTF Powder | High | Excellent (50+) | Light/Medium | Good | Medium |

| Plastisol | Medium | Good (30–40) | Heavy | Poor | Medium |

| Water-based | Very High | Fair (15–25) | Very Light | Excellent | High |

| PU Films | Low-Med | Very Good (40+) | Heavy | Poor | Low |

| Screen Print | Medium | Good (30–40) | Medium | Fair | High |

✅ Fact-check: DTF transfers maintain vibrancy after 50+ washes, while plastisol typically fails at 35–40.

What Technical Specifications Should B2B Buyers Consider?

When selecting powder, evaluate these specifications:

-

Particle Size Distribution: 100–120 µm with narrow variance.

-

Melting Point Range: Typically 160–170°C for reliable transfer.

-

Safety Certifications: Phthalate-free, CPSIA, Oeko-Tex.

-

Shelf Life: 12–24 months with proper storage.

-

Equipment Compatibility: Manual shakers or automated applicators.

📊 Table 4: Technical Specification Comparison

| Specification | Economy Grade | Standard Grade | Premium Grade |

|---|---|---|---|

| Particle Size | 80–150 µm | 100–120 µm | 100–110 µm |

| Melting Point | ±15°C variance | ±7°C variance | ±3°C variance |

| Washfastness | Grade 3 | Grade 4 | Grade 4–5 |

| Coverage Rate | 12–15 g/m² | 10–12 g/m² | 8–10 g/m² |

| Shelf Life | 6–8 months | 12 months | 18–24 months |

| Certifications | Minimal | Basic safety | Full safety |

✅ Fact-check: Premium powders reduce application errors by up to 37%, saving costs on waste and rework.

How Can DTF Powder Quality Impact Production Efficiency?

Powder quality is a major factor influencing throughput, yield, and customer satisfaction.

Business Impacts:

-

Production Throughput: Premium powders = fewer reworks, more consistent curing.

-

Transfer Quality: Softer hand feel, sharper detail, higher wash durability.

-

Cost Efficiency: Lower waste, better coverage efficiency.

📊 Table 5: Business Metrics

| Metric | Low-Quality Powder | Premium Powder | ROI Impact |

|---|---|---|---|

| Waste | 10–15% | 3–5% | -7–10% cost |

| Rework Rate | 8–12% | 1–3% | -5–9% labor |

| Customer Returns | 3–5% | <1% | -2–4% revenue |

| Production Speed | Inconsistent | Optimized | +15–20% capacity |

| Coverage Rate | 12–15 g/m² | 8–10 g/m² | +20–30% savings |

✅ Fact-check: ROI studies show premium powders deliver 2.7x return by reducing rework, waste, and warranty claims.

Conclusion

DTF powder is not just another consumable — it is the adhesive backbone of the Direct to Film process.

For B2B businesses in garment decoration, powder selection determines:

-

Durability of transfers

-

Production efficiency

-

Customer satisfaction

👉 By choosing premium powders and understanding their specifications, apparel businesses can improve quality, reduce costs, and increase competitiveness.