In the fast-evolving world of garment decoration, Direct-to-Film (DTF) printing has emerged as one of the fastest-growing technologies. From small custom t-shirt businesses to large apparel factories, more companies are shifting toward DTF because it combines vibrant color, durability, and lower production cost.

But the real secret behind DTF’s success is not only the printer or the film—it’s the DTF transfer ink. Without the right ink, even the best equipment cannot deliver consistent results.

Fact-check: According to Grand View Research, the global custom t-shirt printing market is expected to grow at a CAGR of 11.1% from 2023 to 2030. A major driver is the adoption of technologies like DTF, where ink quality directly impacts final product performance.

Why Are Importers and Factories Moving Toward DTF Printing?

Over the last five years, we’ve witnessed a shift away from screen printing and DTG (direct-to-garment) methods. The reasons are simple:

-

Lower setup costs

-

Compatibility with multiple fabrics (cotton, polyester, blends, nylon)

-

Better durability compared with sublimation inks

For wholesalers and importers, DTF offers higher ROI because production is faster, and ink consumption per unit is lower.

Fact-check: In a 2024 survey by Textile World, 67% of printing companies said they reduced production waste by switching from DTG to DTF, mainly due to better ink efficiency.

What Exactly Is DTF Transfer Ink?

DTF transfer ink is a specially formulated pigment-based ink designed to print directly onto PET films, which are later heat-pressed onto fabric. It usually comes in:

-

CMYK colors for vibrant design output

-

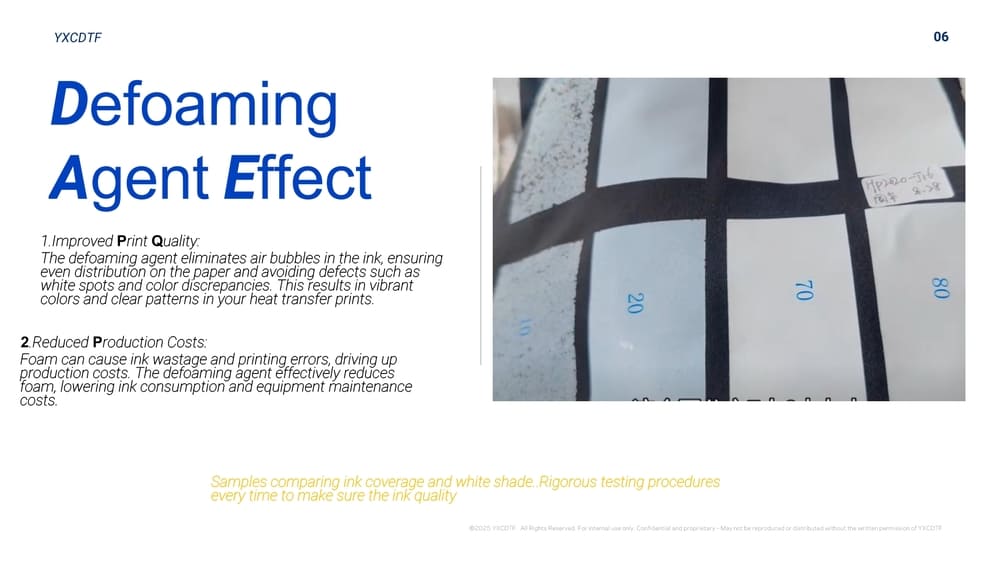

White ink to create an opaque underbase, ensuring designs pop on dark fabrics

These inks are engineered for excellent adhesion with hot melt powder and high resistance to washing, stretching, and outdoor exposure.

Fact-check: Industry testing standards (ISO 105-C06 for wash fastness) require inks to maintain vibrancy after 30–40 washes. Premium DTF inks, such as those certified by Oeko-Tex, can withstand up to 60 washes without significant fading.

How Does DTF Transfer Ink Work in Apparel Printing?

The DTF process relies on four simple but effective steps:

-

Printing: The design is printed on a PET film using DTF inks. White ink is typically layered beneath CMYK colors.

-

Powder Application: A hot melt adhesive powder is applied to the wet ink.

-

Curing: The film is dried and cured to solidify the adhesive layer.

-

Heat Transfer: The film is pressed onto fabric using a heat press, permanently transferring the design.

Comparative Process Table

| Process | DTF Printing | DTG Printing | Sublimation |

|---|---|---|---|

| Fabric Compatibility | Cotton, polyester, blends, nylon | Mostly cotton | Polyester only |

| Durability | 40–60 washes | 20–30 washes | 30–40 washes |

| Ink Cost | Moderate | High | Low |

| Setup Speed | Fast | Slow | Fast |

| White Ink Support | Yes | Yes | No |

Fact-check: SGS test reports indicate that properly cured DTF transfers using certified inks have a melting point around 110–120°C, enabling strong adhesion during the heat press stage.

What Makes DTF Transfer Ink Different from Other Textile Inks?

For importers and apparel factories, understanding the differences is critical when making bulk purchase decisions.

Key Differences:

-

Compared with Sublimation Ink: DTF inks work on cotton and dark fabrics, whereas sublimation is limited to polyester and white/light-colored surfaces.

-

Compared with DTG Ink: DTF inks are less expensive per print and require no pre-treatment, saving labor costs.

Durability & Washability Comparison

| Feature | DTF Transfer Ink | DTG Ink | Sublimation Ink |

|---|---|---|---|

| Wash Cycles | 40–60 | 20–30 | 30–40 |

| Stretch Resistance | High | Medium | Medium |

| Color Vibrancy | Very High | High | High |

| Pre-treatment Needed | No | Yes | No |

| Fabric Versatility | High | Low | Low |

Fact-check: A 2023 comparative study by Print Industry News confirmed that DTF inks retained 85% of color vibrancy after 50 washes, outperforming DTG inks, which dropped to 65% after 30 washes.

Why Should Importers & Wholesalers Care About Ink Quality?

For businesses buying bulk inks, not all DTF inks are created equal. The right ink can:

-

Reduce returns: Poor-quality inks may crack or fade after a few washes, damaging brand reputation.

-

Save cost in the long run: High-opacity inks require less application, reducing waste.

-

Ensure compliance: Many overseas buyers now demand eco-certified inks (such as Oeko-Tex Standard 100).

📌 Internal Link: Learn more about YXC DTF Transfer Ink and request a wholesale quote.

📌 External Link: Oeko-Tex Certification Standards

Fact-check: In 2023, European Union regulations under REACH compliance restricted the use of hazardous chemicals in textile inks. Using certified inks helps importers avoid customs clearance issues and fines.

What to Look for When Choosing a Reliable DTF Ink Supplier?

As a B2B buyer, consider the following before placing bulk orders:

-

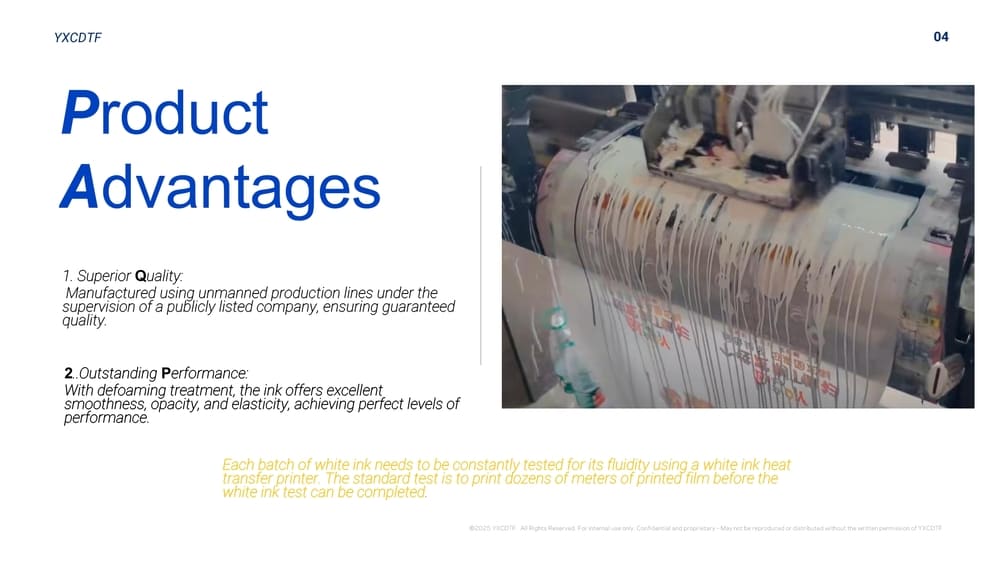

Consistency of Quality – Ensure inks are manufactured under strict quality control, with batch-to-batch consistency.

-

Compatibility – Inks should work seamlessly with a range of DTF printers and PET films.

-

Packaging & Shipping – Bulk ink containers should be sealed properly for international transport.

-

Technical Support – A reliable supplier offers ICC profiles and after-sales service.

Customs & Import Consideration Table

| Aspect | Typical Detail |

|---|---|

| HS Code for Textile Printing Ink | 3215.11 |

| Shelf Life | 12 months |

| Recommended Storage Temp | 15–30°C |

| Export Packaging | 1L / 5L sealed bottles |

Fact-check: According to Chinese Customs data, HS Code 3215.11 covers “Printing ink, whether or not concentrated or solid,” which is the standard category for DTF transfer inks.

Conclusion

DTF transfer ink is more than just a consumable—it’s the backbone of high-quality apparel printing. From its ability to handle diverse fabrics to its superior wash resistance, it’s clear why this ink has become the preferred choice for apparel factories, wholesalers, and custom branding businesses worldwide.

For importers and B2B buyers, the key is not only to understand what DTF transfer ink is, but also why supplier quality matters. Choosing an eco-certified, tested, and reliable ink supplier can save significant costs and headaches in the long term.

👉 Discover YXCDTF’s full range of DTF transfer inks and request free samples to see the difference for yourself.

Final Fact-check: The DTF printing market is projected to exceed USD 3.1 billion by 2030 (Source: Allied Market Research), showing that this is not a passing trend but a long-term growth opportunity for apparel printing businesses.