DTF (Direct-to-Film) printing is transforming the garment industry worldwide. At the core of this technology lies a material that often gets less attention but is absolutely critical — DTF PET Film.

For importers, wholesalers, and garment factories, understanding PET film is not only about product knowledge. It’s about cutting costs, improving efficiency, and ensuring consistent production quality.

📊 Fact-check: According to Grand View Research (2024), the global textile printing market is growing at a CAGR of 9.1% through 2030, with DTF technology leading adoption.

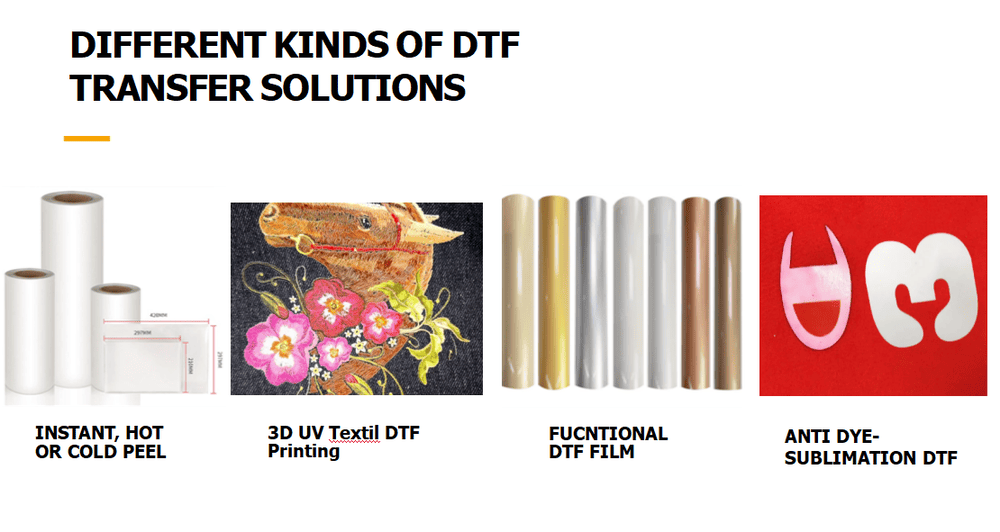

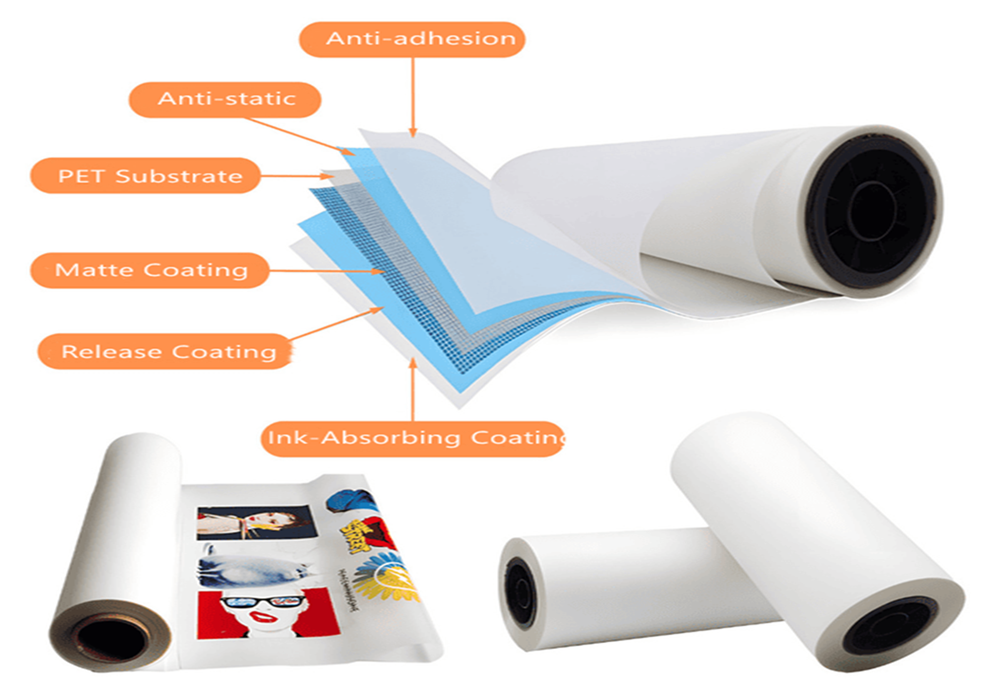

What Exactly is DTF PET Film?

DTF PET Film (Polyethylene Terephthalate film) is a specially coated polyester-based transfer film. It acts as the carrier sheet where designs are first printed before being heat-transferred onto fabrics.

Key Properties:

-

Thickness: 75μm or 100μm

-

Surface: Matte or glossy

-

Coating: Ink-absorbing, anti-static, heat-resistant

-

Peeling Types: Hot peel or cold peel

✅ Fact-check: Unlike packaging PET film, DTF PET films undergo release coating treatments to ensure smooth ink adhesion and consistent transfer (FESPA, 2024).

👉 In short, this film is the foundation of successful DTF printing.

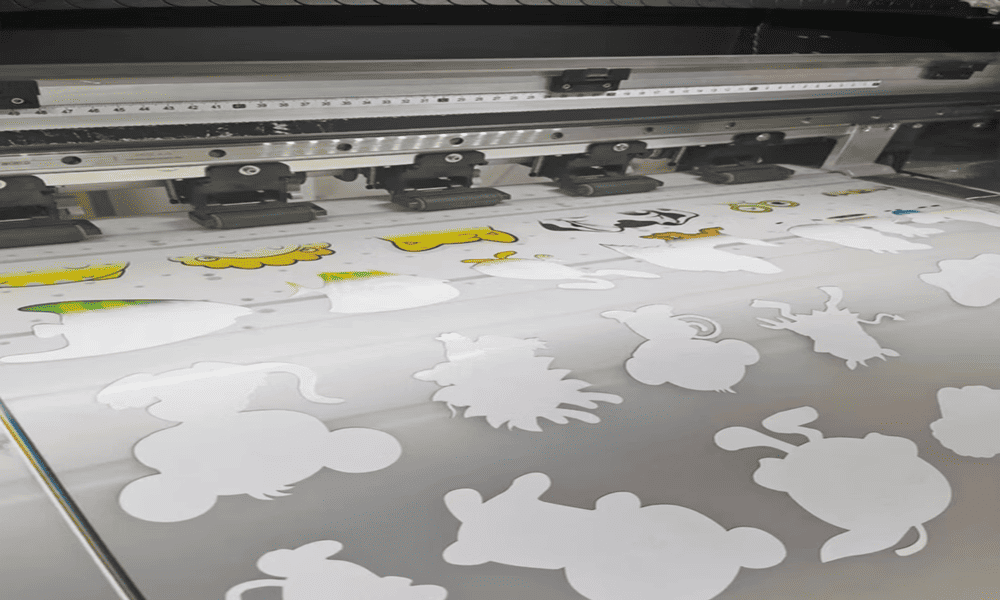

How Does DTF PET Film Work in Printing?

The DTF printing workflow involves several technical stages where PET film plays a central role.

Workflow Steps:

-

Design Printing → Inks are printed directly on PET film (CMYK + white base).

-

Powder Application → Hot melt adhesive powder is applied.

-

Curing → Powder is melted at 110–120°C to create an adhesive layer.

-

Heat Transfer → Film is pressed onto fabric at 160–170°C, 15–20 sec, 3–5 bar.

-

Peeling → Hot peel (immediate) or cold peel (after cooling).

-

Final Press → Optional second press for durability.

Key Technical Parameters:

-

Printing Resolution: Recommended 1440 × 1440 dpi

-

Surface Tension: Optimal 36–38 dynes/cm for ink spread

-

Peel Force: Hot peel: 5–15 gf/inch | Cold peel: 20–30 gf/inch

✅ Fact-check: Controlled surface tension improves print consistency by 20% and increases transfer success rates above 98% (Printing United Alliance, 2024).

Why is DTF PET Film Important for Apparel Production?

For apparel producers, PET film affects not only print quality but also production economics.

Key Benefits:

-

Bright Colors & Fine Detail

-

High Wash Durability (50+ washes)

-

Stretchability for sportswear

-

Cost savings vs screen printing

-

Compatible with cotton, polyester, blends, nylon, leather

📊 Comparison Table

| Feature | DTF PET Film | Screen Printing | Sublimation | Heat Transfer Vinyl |

|---|---|---|---|---|

| Fabric Compatibility | Cotton, Polyester, Blends, Nylon | Mostly Cotton | Polyester Only | Limited |

| Setup Costs | Low | High (screens) | Medium | Low |

| Color Vibrancy | High | High | Medium | Medium |

| Wash Durability | 50+ washes | 40–50 washes | 30–40 washes | 20–30 washes |

| Detail Accuracy | Excellent | Limited | Good | Limited |

| Production Speed | Fast, digital | Slower | Medium | Slow |

✅ Fact-check: DTF reduces setup costs by up to 40% compared to screen printing (Printwear & Promotion, 2023).

What Should Importers and Wholesalers Look For in PET Film?

Not all PET films are created equal. Here’s what professionals should check:

Buyer’s Checklist:

-

Thickness Tolerance: ±2 μm maximum.

-

Peel Force Range: Hot peel: 5–15 gf/inch | Cold peel: 20–30 gf/inch.

-

Coating Uniformity: Error < ±5%.

-

Anti-static Resistance: Surface resistance 10^9–10^11 Ω.

-

Moisture Resistance: Absorption < 0.5% for export safety.

✅ Fact-check: YXCHTV applies 100% peel force testing and humidity aging tests (40°C, 90%RH, 72h) before export.

👉 Always request supplier certificates: ISO 9001, SGS, MSDS, COA.

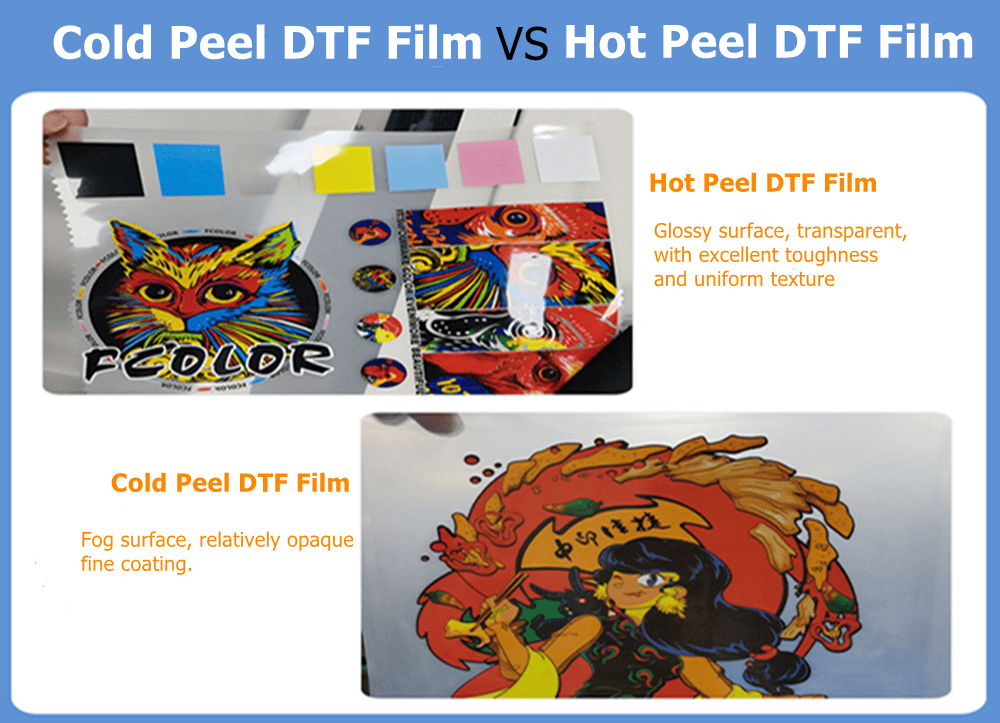

How to Choose Between Hot Peel and Cold Peel PET Film?

Both types serve different production needs.

📊 Hot vs Cold Peel Comparison

| Feature | Hot Peel PET Film | Cold Peel PET Film |

|---|---|---|

| Peel Timing | Immediate | After cooling |

| Efficiency | Higher (fast runs) | Medium |

| Detail Retention | Good | Excellent |

| Best for | Large runs | Complex logos |

| Cost | Slightly higher | More economical |

✅ Fact-check: Hot peel improves throughput by 25%, while cold peel offers sharper detail (Printing United Alliance, 2024).

👉 Recommendation:

-

Factories → Hot peel for efficiency.

-

Small shops → Cold peel for detail precision.

Global Sourcing and Supply Chain Considerations

Why Choose YXDTF PET Film?

-

Mature DTF supply chain

-

Cost-effective pricing

-

Reliable bulk capacity

Certifications to Request:

-

ISO 9001

-

OEKO-TEX / SGS safety compliance

-

MSDS for chemical safety

Logistics:

-

HS Code: 3920.62 or 3920.69

-

Tariffs: US ~6.5%, EU ~6–8%

-

Packaging: Moisture-proof vacuum + reinforced cartons + pallets

✅ Fact-check: China Customs data (2024) reports a 20% YoY increase in DTF PET Film exports, with Europe & US taking 65% of volume.

🔗 Learn more about our YXCDTF DTF PET Film.

🔗 See FESPA’s report on DTF technology growth.

Conclusion: PET Film as the Backbone of DTF Printing

DTF PET Film is not just another consumable — it’s the backbone of digital garment decoration.

For B2B buyers, it impacts:

-

Print durability

-

Production efficiency

-

Customer satisfaction

📌 Final Fact-check: Allied Market Research (2024) projects double-digit growth in PET film consumption through 2030, driven by on-demand fashion.

👉 If you’re an importer, wholesaler, or apparel factory looking for reliable PET Film, partner with YXCDTF for consistent quality and competitive supply.