Raised logos and three-dimensional branding elements are widely used in modern apparel and accessories. From sports jerseys and workwear to T-shirts, bags, caps, and footwear, 3D heat transfer patches have long been a standard solution for adding visual impact and brand recognition.

However, as apparel production shifts toward shorter lead times, higher customization, and more sustainable manufacturing, traditional 3D heat transfer patch processes are increasingly being re-evaluated. In this context, 3D UV DTF printing has emerged as a new production approach that addresses many of the efficiency and flexibility limitations of conventional methods.

This article compares 3D UV DTF with traditional 3D heat transfer patches from a manufacturing perspective, focusing on process logic, production efficiency, surface effects, and future industry trends.

![]()

What Are Traditional 3D Heat Transfer Patches?

Traditional 3D heat transfer patches1 are typically produced through multi-step processes such as molding, layering, foaming, or simulated embroidery techniques. The patch is manufactured separately and later applied to the garment or product using heat and pressure.

Common characteristics include:

- Multiple production steps2 and longer setup times

- Heavy reliance on molds, plates, or manual operations

- Limited flexibility for small-batch or frequently changing designs

- Material waste generated during sampling and adjustments

These processes are proven and capable of delivering strong visual impact, but they are generally optimized for large, stable orders rather than modern, flexible production environments.

What Is 3D UV DTF Printing?

3D UV DTF is a digital transfer printing process that uses UV-curable inks and adhesives to build thickness and texture directly on a film. The printed graphic is then transferred onto textiles or soft goods using controlled pressure and minimal heat.

Unlike traditional patch production, the dimensional effect in UV DTF is created during the printing stage, not through secondary forming or molding processes.

Modern Textile UV DTF vinyl solutions allow precise control over layer thickness, edge definition, and surface finish without the need for molds or complex tooling.

Process Comparison: Traditional Patches vs 3D UV DTF

Traditional 3D Heat Transfer Patches

- Mold or plate preparation

- Multi-layer forming or foaming

- Intermediate drying or curing

- Manual trimming and finishing

- Heat transfer application

Each step increases lead time and introduces potential variability.

3D UV DTF Printing

- Digital design preparation

- Layer-by-layer UV printing and curing

- Transfer preparation

- Application to the final product

By integrating thickness creation directly into the printing process, 3D UV DTF significantly simplifies the overall workflow.

Production Efficiency and Scalability

From a production standpoint, efficiency is one of the strongest advantages of 3D UV DTF1.

Compared with traditional 3D heat transfer patches2, UV DTF offers:

- Faster turnaround times

- Minimal setup and changeover requirements

- Easy handling of small batches and customized orders

- Reduced dependency on skilled manual labor

For manufacturers and distributors serving multiple clients with frequent design updates, 3D UV DTF provides a more scalable and responsive production model.

Environmental and Sustainability Considerations

Traditional patch production often generates material waste from molds, excess materials, and rejected samples. Longer production cycles also lead to higher energy consumption.

3D UV DTF improves sustainability at the process level by:

- Reducing material waste through precise digital printing

- Eliminating the need for molds and plates

- Using controlled ink and adhesive application

- Shortening overall production cycles

While sustainability depends on full production management, UV DTF offers a more environmentally conscious alternative to many traditional patch processes.

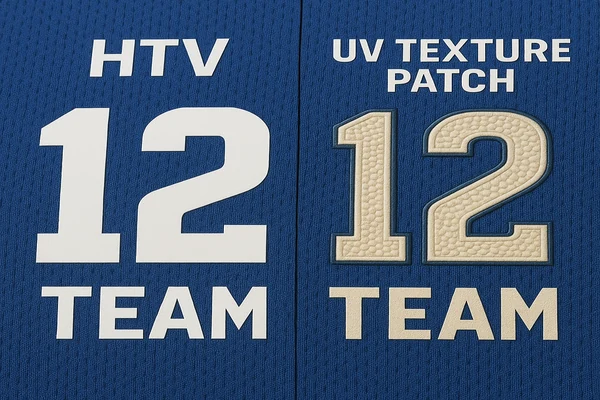

Surface Effects and Design Possibilities

One of the most distinctive advantages of 3D UV DTF is its ability to create diverse surface textures without increasing production complexity.

Typical effects include:

- Glossy and high-shine finishes

- Embroidery-like raised textures

- Metallic surface effects

- Glitter and decorative finishes

- Woven or fabric-simulated textures

These effects are often difficult or costly to achieve consistently using traditional 3D heat transfer patch methods.

Typical Applications of 3D UV DTF Patches

In apparel and accessory production, both traditional patches and 3D UV DTF are primarily used for logos, branding elements, and decorative details.

Common applications include:

- Sports jerseys and team uniforms

- Workwear and industrial uniforms

- T-shirts and casual apparel

- Bags and backpacks

- Caps and hats

- Shoes and footwear

For products requiring frequent design changes, short production runs, or multiple surface effects, 3D UV DTF offers clear operational advantages.

Limitations and Practical Considerations

Despite its advantages, 3D UV DTF is not intended to replace all traditional patch processes.

Key considerations include:

- Not ideal for large full-coverage designs

- Proper matching between adhesive and substrate is essential

- Process control is required to ensure batch consistency

Professional manufacturers often integrate 3D UV DTF as a complementary solution rather than a complete replacement.

Why 3D UV DTF Is a Growing Trend

The growing adoption of 3D UV DTF reflects broader industry trends toward efficiency, customization, and sustainable production. By simplifying workflows while expanding design possibilities, UV DTF aligns well with modern apparel and accessory manufacturing needs.

For printers, brands, and distributors, understanding where 3D UV DTF delivers real operational value is essential for long-term competitiveness.

Conclusion

Traditional 3D heat transfer patches have played an important role in apparel decoration for many years. However, 3D UV DTF introduces a more efficient, flexible, and environmentally conscious approach to creating raised logos and dimensional branding elements.

By reducing production complexity and enabling a wide range of surface textures, 3D UV DTF vinyl solutions represent a meaningful evolution in patch and logo production for modern apparel and soft goods manufacturing.