As apparel factories expand their decoration capabilities, many face a recurring decision: should they rely on DTF transfer film, or introduce textile UV DTF vinyl into their production line? Although both technologies are widely used in garment decoration, they represent fundamentally different production logics.

The most common mistake factories make is treating this choice as a material comparison. In reality, choosing between DTF transfer film and textile UV DTF vinyl means choosing between two production systems, each with its own cost structure, risk profile, and operational constraints.

This article explains the key differences from a factory perspective and helps apparel manufacturers make informed, production-oriented decisions.

What Is DTF Transfer Film and Textile UV DTF Vinyl?

DTF transfer film is a flexible, fabric-friendly printing system designed for full-area garment decoration, while textile UV DTF vinyl is a structured, thick-label decoration solution optimized for logos and branding in low-stretch areas. Apparel factories should choose based on order type, placement requirements, and acceptable production risk.

Rather than comparing specifications or visual effects, this guide evaluates both technologies from the standpoint of factory operations. We will examine production logic, workflow impact, cost structure, and risk exposure to help factories decide which solution—or combination—fits their business model.

What Production Logic Does DTF Transfer Film Represent?

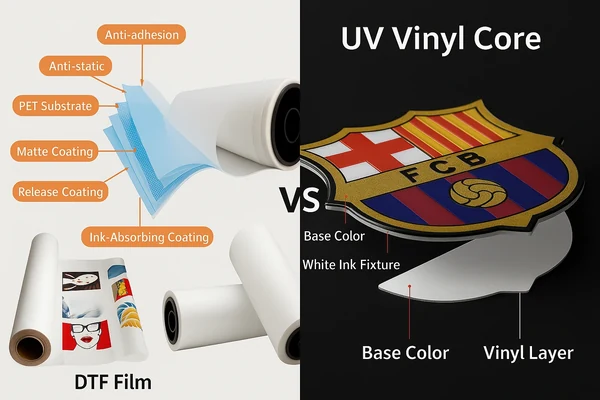

DTF transfer film1 represents a fabric-first printing system2 designed to adapt to a wide range of garments and production conditions.

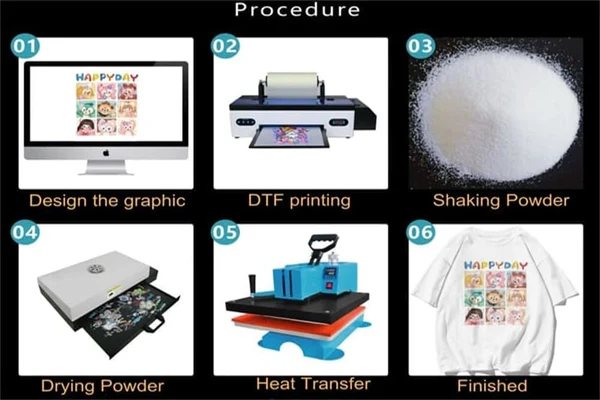

At its core, DTF focuses on flexibility and compatibility. Graphics are printed onto a coated transfer film, combined with adhesive powder, and heat-transferred onto fabric. Once applied, the print becomes part of the garment surface and can tolerate normal fabric movement.

From a factory standpoint, DTF offers strong adaptability. It works across cotton, polyester, blends, and many functional fabrics. It also supports both large-area prints and detailed graphics, making it suitable for varied order types.

For factories evaluating real production parameters, technical details and film configurations are outlined in

👉 DTF Transfer Film product specifications.

What Production Logic Does Textile UV DTF Vinyl Represent?

Textile UV DTF vinyl represents a different philosophy: structured decoration rather than flexible printing.

This system uses UV printing to create thick, raised graphics on a vinyl substrate, which are then transferred onto garments via heat press. The result is a logo or label-like decoration with strong visual presence and dimensional stability1.

Unlike DTF, textile UV DTF vinyl2 is not designed to stretch with the fabric. Its value lies in shape retention, edge definition, and premium branding appearance. Placement must be limited to low-stretch zones such as chest logos, sleeves, or decorative panels.

Factories considering this route should review material structure and application limits via

👉 Textile UV DTF Vinyl product specifications.

Key Differences That Matter to Apparel Factories

From a factory perspective, the most important differences are operational rather than aesthetic.

DTF transfer film supports a wide range of fabrics and allows for full-area decoration. It tolerates garment movement and washing better in stretch-prone areas. However, it requires careful control of powder application, curing, and environmental conditions.

Textile UV DTF vinyl delivers superior visual impact and consistency for logos but introduces stricter placement rules. Because it forms a thick, rigid layer, misuse in stretch areas increases the risk of cracking or edge lifting.

In short, DTF prioritizes versatility, while UV DTF vinyl prioritizes structure and branding precision.

Order Types: Which Technology Fits Which Orders?

Order structure should guide technology choice.

DTF transfer film is better suited for bulk apparel orders, full-front prints, fashion graphics, and orders involving multiple fabric types. It performs well when flexibility and coverage are required.

Textile UV DTF vinyl is ideal for logo-focused orders, branding elements, small-batch customization, and applications where visual differentiation matters more than coverage.

Factories handling diverse order profiles often benefit from treating DTF as the core printing system and UV DTF vinyl as a supplementary branding solution.

Typical Use Scenarios: Where Each Technology Is Actually Used

Understanding real-world use scenarios is often more practical than comparing technical parameters alone. In apparel factories, DTF transfer film and textile UV DTF vinyl are typically used in very different application contexts.

DTF transfer film is most commonly used for flexible, full-area garment decoration. Typical applications include T-shirt customization, canvas tote bags, hoodies, sweatshirts, and casual apparel where the printed design needs to move naturally with the fabric. Because DTF prints integrate closely with the textile surface, this system is well suited for fashion graphics, promotional prints, and designs covering larger areas.

Textile UV DTF vinyl1, also known as 3D UV DTF vinyl, is primarily used for logo-style and branding-focused applications. Common use cases include shoe labels, cap logos, jackets, outerwear, backpacks, and luggage branding. One of the most popular applications today is sports jerseys, where raised logos and team branding are applied to controlled, low-stretch zones for strong visual impact.

These usage patterns clearly reflect the core difference between the two systems: DTF transfer film2 functions as a printing solution for flexible surfaces, while textile UV DTF vinyl functions as a structured decoration solution for branding elements.

Cost & Risk Comparison from a Factory Perspective

Material cost alone does not reflect true production cost.

DTF transfer film introduces risks related to powder control, humidity sensitivity, and curing consistency. These risks scale with production volume and environmental instability.

Textile UV DTF vinyl reduces variability in visual output but increases risk if applied incorrectly. Improper placement or misuse on stretch zones can result in immediate customer complaints rather than gradual degradation.

The highest cost is not choosing the “wrong material,” but choosing the wrong system for a specific order type.

How Should Apparel Factories Choose Between the Two?

There is no universal answer, and factories are not required to choose only one system.

Factories should start by answering three questions:

- Where will the decoration be placed on the garment?

- Does the order prioritize flexibility or visual structure?

- What level of rework and rejection can the production line tolerate?

DTF transfer film should be the primary choice for flexible, full-area decoration. Textile UV DTF vinyl should be introduced selectively for branding-focused applications where placement and structure are controlled.

Attempting to replace one system entirely with the other often increases operational risk rather than reducing cost.

Conclusion

DTF transfer film and textile UV DTF vinyl are not competing materials but complementary production systems. Each is optimized for different garment behaviors and order requirements.

For apparel factories, the correct decision is not about which technology is better, but which technology aligns with specific production goals. Understanding these boundaries allows factories to reduce defects, control costs, and deliver consistent results to their clients.