I once faced a difficult decision when choosing materials for apparel customization. Cost control, production efficiency, and final print quality all felt risky if I made the wrong choice.

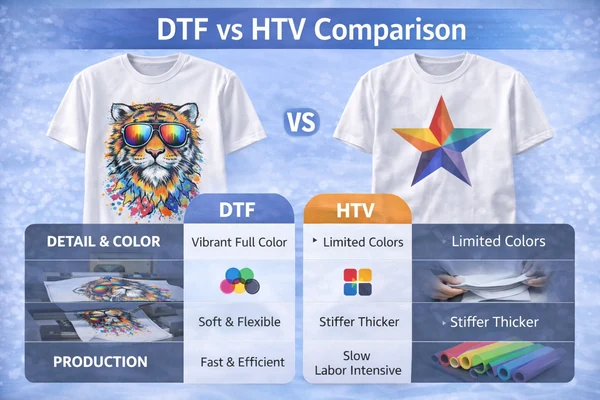

DTF and HTV each offer clear advantages. There is no absolute winner. The better option depends on your design needs, production scale, and business goals.

As a product-focused company, YXCDTF understands how critical material selection is for apparel customization. In recent years, Direct to Film printing has become a popular alternative to traditional Heat Transfer Vinyl. Understanding the real differences between these two methods helps businesses make confident and informed decisions.

In addition to traditional flat transfer solutions, some brands are also exploring Textile UV DTF Vinyl for 3D, textured, and premium decorative effects, especially in logo and branding applications.

Learn more about DTF Transfer Film

What Is Heat Transfer Vinyl (HTV)?

I started my apparel customization journey with heat transfer vinyl, and it remains a core solution for many brands today.

Heat Transfer Vinyl (HTV) is a special vinyl material that is cut into shapes or letters and then heat-pressed onto fabric surfaces.

HTV works through a cut-and-press workflow. I first create the artwork in graphic software, then use a cutting plotter to cut the design from vinyl sheets. After cutting, excess vinyl must be manually weeded out. The final design is transferred onto the garment using a heat press.

This process makes HTV especially suitable for simple graphics, solid colors, lettering, and textured finishes1. YXCDTF supplies a wide range of heat transfer materials, including glitter, flock, metallic, holographic, matte, puff, and textured vinyl solutions.

HTV is compatible with cotton, polyester, cotton blends, canvas, spandex, and lycra. When applied correctly and cared for properly, HTV prints can withstand repeated washing without cracking or peeling. Because the equipment requirements are relatively simple, HTV is ideal for startups, small businesses, and fashion-driven collections.

What Is Direct to Film Printing (DTF)?

As customer demand shifted toward more detailed and colorful designs, I began using DTF printing more frequently.

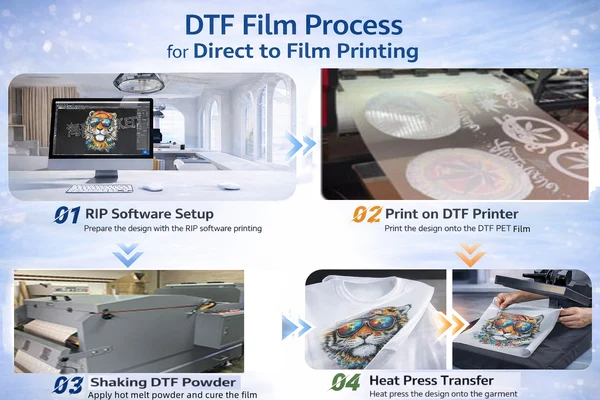

Direct to Film (DTF) printing transfers full-color designs by printing onto a special PET film and then heat-pressing the image onto fabric.

DTF follows a printing-based production logic. The design is printed directly onto coated PET film using CMYK and white inks. While the ink is still wet, hot-melt adhesive powder is applied evenly. The film is then heat-cured, making it ready for transfer.

DTF’s biggest strength lies in color richness and fine detail reproduction2. Gradients, small text, complex logos, and multi-color artwork can be produced without cutting or weeding.

DTF also offers strong fabric adaptability3. Because transfers can be prepared in advance and stored, DTF supports efficient batch production.

DTF Transfer Film specifications

Key Differences Between HTV and DTF

Many production mistakes happen when the fundamental differences between these two methods are misunderstood.

HTV is a cutting-based decoration method, while DTF is a printing-based transfer technology.

| Comparison Item | HTV (Heat Transfer Vinyl) | DTF (Direct to Film) |

|---|---|---|

| Application Process | Design → Cut → Weed → Heat Press | Print → Powder → Cure → Heat Press |

| Design Complexity | Simple shapes and lettering | Complex, multi-color, fine detail |

| Production Efficiency | Manual, labor-intensive | Scalable, batch-friendly |

| Visual Effect | Flat or textured vinyl | Flat printed graphics |

| Best Use Case | Fashion effects, lettering | Logos, illustrations, gradients |

Where Textile UV DTF Vinyl Fits In

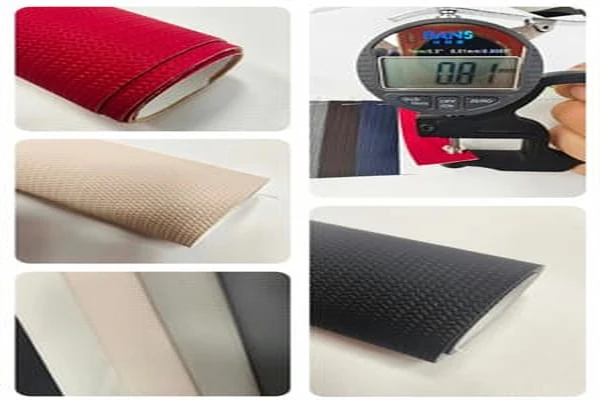

While both HTV and DTF focus on flat surface decoration, some brands require stronger visual depth and tactile impact.

Textile UV DTF Vinyl is designed for 3D, textured, and raised decorative effects on fabric.

Unlike traditional DTF transfer film, Textile UV DTF Vinyl is typically made from TPU or PU materials and creates visible thickness and surface texture after transfer. It is not designed for elasticity or stretch performance.

Typical use cases include:

- Raised logos

- Premium branding elements

- Decorative patches and emblems

- High-end apparel collections

Textile UV DTF Vinyl solutions

Why Work With YXCDTF?

After years of serving B2B customers, we clearly understand their real concerns.

Consistency, predictable cost, and reliable supply define long-term success.

YXCDTF is based in China and focuses on supplying high-quality, cost-effective DTF transfer film and related heat transfer materials to importers in Europe, North America, and South America. We maintain stable raw material inventory, operate controlled production environments, and support OEM packaging and bulk supply.

Conclusion

HTV and DTF each have clear strengths. The best choice depends on your production model, design complexity, and growth strategy.

For flat, detailed, and scalable apparel printing, DTF transfer film remains the core solution.

For fashion-driven visual effects, HTV continues to play an important role.

For premium branding requiring 3D texture and raised surface impact, Textile UV DTF Vinyl offers a distinct decorative option.

Explore this link to understand how simple graphics enhance the appeal and effectiveness of HTV designs. ↩

Explore this link to understand how DTF printing enhances design quality with vibrant colors and intricate details. ↩

Discover how DTF's adaptability to various fabrics can improve your printing options and efficiency. ↩