Many buyers rush into UV DTF without knowing the systems. I have seen factories lose money fast. The wrong choice often looks fine at first, then fails in use.

Textile UV DTF Vinyl is made for fabrics and heat transfer, while UV DTF AB Film is made for hard surfaces using cold transfer. They solve different problems and cannot replace each other in real production.

I wrote this guide after seeing the same mistake again and again. Buyers compare ink, printers, or price. They skip system logic. That is why peeling and cracking happen later. If you keep reading, you will avoid that path.

What Is Textile UV DTF Vinyl Designed For?

Textile UV DTF Vinyl often gets misunderstood because it has “UV DTF” in its name. I also made this mistake early on when I first tested samples.

Textile UV DTF Vinyl is designed for apparel and textile decoration where shape, thickness, and visual impact matter more than stretch.

In real use, this material behaves like a structured label. I press it onto fabric using heat. It sits on top of the textile instead of soaking in. That is the whole point. The result looks sharp and strong. Logos stay clear. Edges stay clean. The surface feels solid.

The vinyl itself is thick by design. It does not try to stretch with the fabric. That is why I only place it on low-stretch zones like chest logos, shoulder marks, bags, caps, or shoes. When I follow this rule, durability is stable.

Below is how I explain it to buyers in simple terms:

| Feature | Textile UV DTF Vinyl |

|---|---|

| Target material | Fabric, apparel, bags |

| Transfer method | Heat press |

| Material feel | Thick, raised, structured |

| Stretch tolerance | Low to medium |

| Visual style | 3D, label-like, bold |

This system exists because many brands want texture and structure. It is not a compromise. It is a clear design choice.

👉 Textile UV DTF Vinyl product specifications.

What Is UV DTF AB Film Actually Designed For?

UV DTF AB Film is a completely different system, even though the name sounds similar. I treat it as a separate category in my workflow.

UV DTF AB Film is designed for rigid or semi-rigid surfaces using a cold transfer process without heat.

The system uses two films. The A film receives the UV ink. The B film carries the adhesive transfer layer. After printing and lamination, I transfer the graphic by pressure. No heat is needed. This makes it perfect for glass, metal, plastic, acrylic, and coated wood.

The key point is surface stability. These materials do not stretch. They do not compress. They do not wrinkle. That is why the thin UV layer stays bonded.

Here is how I break it down:

| Feature | UV DTF AB Film |

|---|---|

| Target material | Glass, metal, plastic |

| Transfer method | Cold pressure transfer |

| Material feel | Thin, surface-bonded |

| Stretch tolerance | None |

| Visual style | Smooth, sticker-like |

This system shines in signage, promotional items, bottles, and industrial labels. It was never meant to work on fabric, no matter how good the ink looks on the film.

Key Material and Process Differences That Buyers Miss

Most buyers compare specs. I compare behavior after application. That is where the truth shows up.

Textile UV DTF Vinyl relies on heat and structure. UV DTF AB Film relies on surface adhesion and rigidity.

When I print Textile UV DTF Vinyl1, I expect a thick result. I cut it. I heat press it. The adhesive activates with temperature and pressure. The vinyl locks onto the textile fibers from the top.

With UV DTF AB Film2, the ink layer is thin and hard after curing. It bonds flat onto a smooth surface. There is no room for bending or stretching. That is not a defect. That is the design

This table helps buyers see the system gap clearly:

| Aspect | Textile UV DTF Vinyl | UV DTF AB Film |

|---|---|---|

| Adhesive activation | Heat | Pressure |

| Final thickness | Thick | Thin |

| Flex behavior | Limited | Rigid |

| Wash resistance | Designed for textiles | Not for washing |

| Failure mode | Cracking if overstretched | Peeling on fabric |

Once buyers see this, arguments about price or printer brand disappear.

Why UV DTF AB Film Fails on Apparel Almost Every Time

I have tested this myself more than once. The result is always the same.

UV DTF AB Film fails on apparel because fabric movement creates stress that the rigid UV layer cannot absorb.

Fabric bends when worn. It stretches when pulled. It folds when washed. Each movement pulls against the edge of the UV layer1. Stress builds up. Cracks appear. Edges lift. After one or two washes, customers complain.

This is not an operator issue. This is not a quality issue. This is physics.

Many buyers think stronger glue2 will fix it. It does not. Stronger glue only makes the failure uglier. The material still cannot move with the fabric.

Once I explain this to customers, they stop asking if AB Film can work on shirts. The answer stays no.

Typical Use Cases and Correct Matching

There is no better or worse product here. There is only correct matching.

Textile UV DTF Vinyl belongs on fabrics. UV DTF AB Film belongs on hard goods.

From my daily production view:

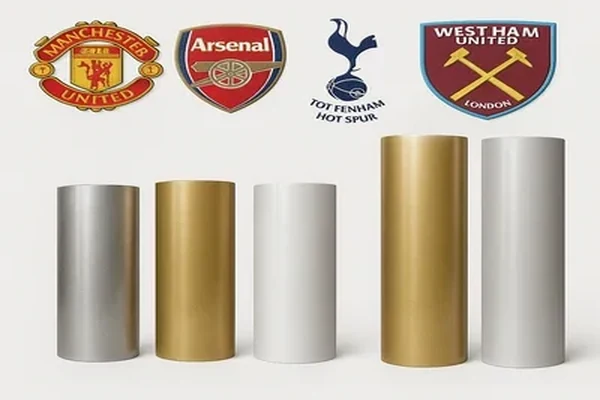

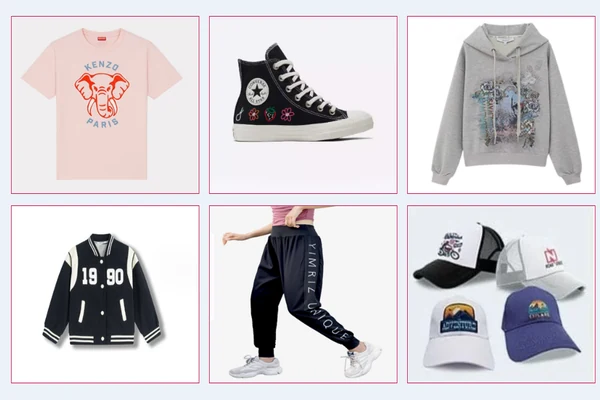

- I use Textile UV DTF Vinyl for T-shirts, uniforms, sportswear logos, tote bags, caps, and footwear panels.

- I use UV DTF AB Film for bottles, phone cases, sign boards, packaging boxes, and metal plates.

When buyers mix systems, they introduce risk. Returns increase. Trust drops. That cost is always higher than choosing correctly at the start.

Buyer Decision Guide Before You Place an Order

I always tell buyers to slow down before paying.

The right choice starts with the surface, not the printer, ink, or price.

I ask three simple questions every time:

- Will the final product stretch, bend, or be washed?

- Is the surface fabric or rigid material?

- Do I want structure or flexibility?

If the answer points to fabric, I move to Textile UV DTF Vinyl. If the answer points to hard goods, I choose UV DTF AB Film. This rule has never failed me.

👉 Textile UV DTF Vinyl product specifications

Conclusion

Textile UV DTF Vinyl and UV DTF AB Film solve different problems. When buyers match system logic to real use, failures drop and production stays stable.