DTF printing and UV DTF printing are often discussed together, yet they serve different production needs. For apparel manufacturers, printers, and distributors, understanding the real differences between these two processes is essential when making purchasing and production decisions.

Rather than asking which technology is “better,” the more practical question is which process is better suited to specific products, workflows, and business models.

This article compares UV DTF printing and DTF printing from a procurement and manufacturing perspective, focusing on process logic, application scope, cost structure, and decision-making factors.

What Is DTF Printing?

DTF (Direct to Film) printing1 is a heat transfer process2 primarily used for textile decoration. Designs are printed onto a PET film using water-based pigment inks, combined with hot-melt powder adhesive, and then transferred onto fabric using heat and pressure.

DTF printing is widely used for:

- Full-color garment graphics

- Medium to large design areas

- Cotton, polyester, and blended fabrics

- T-shirts, hoodies, and casual apparel

Its popularity comes from its versatility and relatively low entry barrier for garment printers.

What Is UV DTF Printing?

UV DTF is a transfer printing process that uses UV-curable inks and adhesives1 to create graphics on a film, which are then transferred onto various substrates.

Unlike traditional DTF, UV DTF does not rely on powder adhesive or fabric penetration. Instead, it forms a surface-level graphic2 with strong adhesion and optional dimensional (3D) effects.

Modern Textile UV DTF vinyl solutions are specifically developed to allow UV DTF application on apparel and soft goods where surface decoration, logos, and textured branding elements are required.

Core Process Differences

DTF Printing Workflow

- Design preparation

- Inkjet printing on PET film

- Powder adhesive application

- Drying or curing

- Heat transfer to fabric

The process is optimized for covering fabric surfaces with printed graphics.

UV DTF Printing Workflow

- Digital design preparation

- Layer-by-layer UV printing and curing

- Transfer preparation

- Application to the product

UV DTF builds the graphic structure during printing, eliminating powder handling and reducing process steps.

Application Scope Comparison

Where DTF Printing Excels

DTF printing is best suited for:

- Large-area graphics

- Full-color images and gradients

- Soft hand-feel requirements

- Apparel-focused production lines

It integrates easily into garment decoration workflows where fabric flexibility and coverage are priorities.

Where UV DTF Excels

UV DTF is more suitable for:

- Logos and branding elements

- Small to medium-sized graphics

- Raised or textured surface effects

- Apparel and non-apparel substrates

UV DTF is often chosen when visual impact, texture, and precision are more important than full-area coverage.

Visual and Surface Effects

One of the most significant differences between UV DTF and DTF printing lies in surface appearance.

-

DTF Printing:

Produces flat, fabric-integrated prints with a soft feel. -

UV DTF Printing:

Enables glossy finishes, raised textures, embroidery-like effects, metallic looks, glitter effects, and woven appearances.

These effects are difficult or impossible to achieve with standard DTF processes.

Production Efficiency and Workflow Impact

From a manufacturing and procurement perspective:

- DTF printing requires powder handling, drying space, and fabric-focused process control.

- UV DTF offers a cleaner workflow with fewer consumables and simpler process management.

For operations handling frequent design changes, logo customization, or multi-product lines, UV DTF can provide higher operational flexibility.

Cost Structure and Investment Considerations

DTF printing generally has:

- Lower initial equipment costs

- Lower consumable costs for large-area prints

UV DTF typically involves:

- Higher equipment investment

- Higher material precision

- Greater value per printed unit

As a result, UV DTF is often adopted as a value-added process1 rather than a mass-coverage solution.

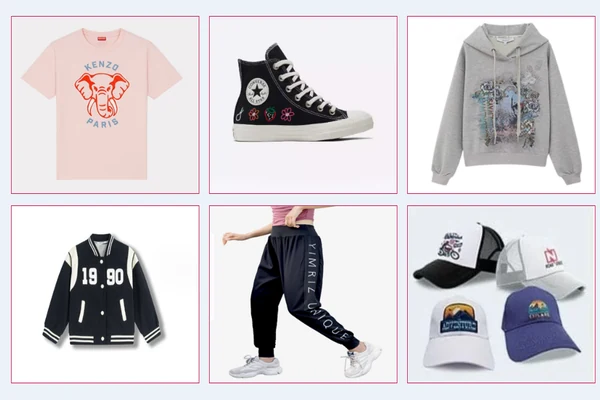

Typical Apparel and Product Applications

Both processes are widely used in apparel manufacturing but serve different roles.

DTF Printing Applications:

- T-shirts and casual apparel

- Promotional garments

- Full-front or back prints

UV DTF Printing Applications:

- Sports jerseys and team uniforms

- Workwear logos

- T-shirts with raised branding

- Bags and backpacks

- Caps and hats

- Shoes and footwear

In many professional production environments, the two processes coexist rather than compete.

How to Choose Between UV DTF and DTF Printing

When evaluating UV DTF vs DTF printing, buyers should consider:

- Size and type of graphics

- Desired surface effect

- Production volume and customization frequency

- Target products beyond apparel

- Long-term differentiation strategy

Choosing the right process is less about replacing one technology and more about building a complementary production system.

Conclusion

DTF printing and UV DTF printing serve distinct purposes within modern apparel and branding production. DTF remains a powerful solution for fabric-based, full-area decoration, while UV DTF excels in logos, textured branding, and surface-level visual effects.

For manufacturers and distributors seeking flexibility, efficiency, and product differentiation, Textile UV DTF vinyl solutions offer a valuable addition to existing DTF workflows rather than a direct replacement.

Understanding these differences allows buyers to make informed, long-term procurement decisions aligned with their production goals.