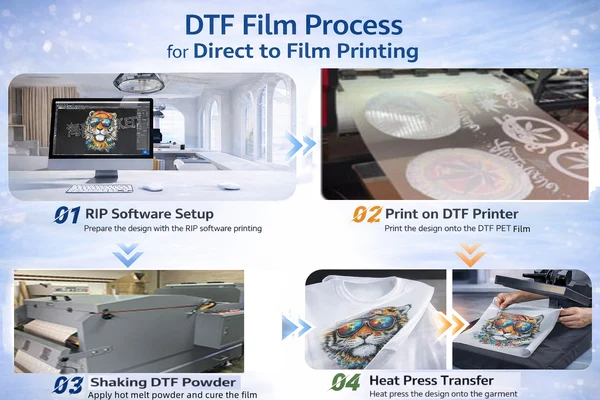

What Is DTF Film and Why Is It Essential for Direct-to-Film Printing?

DTF printing often fails not because of the printer or ink, but because the film is misunderstood or underestimated.

I learned this the hard way—when colors looked dull, powder scattered unpredictably, and prints cracked after washing, changing inks or RIP settings barely helped.

DTF film is a specially engineered PET transfer film that receives ink and hot-melt powder, then releases the design onto fabric, making it the structural foundation of stable and repeatable direct-to-film printing.

Once I stopped treating DTF film as a consumable accessory and started treating it as a core production material, failure rates dropped sharply. That shift completely changed how I evaluate DTF workflows today.

What exactly is DTF film made of?

Many beginners assume DTF film is just a plastic sheet. I thought the same—until production problems made it impossible to ignore.

DTF film is a PET-based transfer medium composed of multiple functional coating layers that collectively control ink absorption, powder adhesion, thermal behavior, and release performance during heat transfer.

Understanding the PET base and coating system (deep dive)

The PET base defines the mechanical stability of the film. High-quality PET remains flat during printing and maintains dimensional stability under heat.

When PET quality is poor, I consistently observe:

- Film edge curling during printing

- Shrinkage during heat press

- Increased head strikes and ink mist contamination

These issues directly increase downtime and maintenance risk.

On top of the PET1 substrate sits the inkjet receptive coating, which determines how ink droplets spread, anchor, and dry.

If this coating absorbs ink unevenly, the result is blurred edges, weak color density, or unstable white ink layers. I test this by printing fine text and thin vector lines—poor coating quality always shows first at small scales.

The release layer sits between the ink/powder composite and the fabric. Its role is critical but often invisible.

If release force is too weak, transfers feel brittle and may crack after washing.

If release force is too strong, peeling becomes inconsistent and damages fine details.

| Layer | Main role | Real production impact |

|---|---|---|

| PET base | Structural stability | Flat feeding, reduced shrinkage |

| Inkjet coating | Ink control | Color density, fine detail |

| Release layer | Transfer behavior | Soft hand feel, clean peel |

| Back coating | Anti-static | Clean powder distribution |

DTF film does not work as a single layer—it works as an integrated system.

Why does DTF film affect print quality so much?

At first, I blamed RIP profiles and ink brands for inconsistent results. Over time, it became clear that film connects every stage of the DTF process.

DTF film determines how ink dries, how powder bonds, and how the final transfer behaves under stretching and washing.

Ink, powder, and film interaction explained

Ink behavior begins the instant droplets land on the film surface.

If absorption is too slow, ink spreads laterally and edges blur.

If absorption is too fast, ink penetration becomes uneven and colors appear dry or grainy.

White ink2 is especially sensitive due to its higher pigment load.

High-quality film stabilizes white ink laydown and reduces oil separation. Poor film often leads to white cracking or flaking after washing.

Powder adhesion depends entirely on wet ink control.

If the film dries unevenly, powder sticks where it should not, creating thick edges and brittle transitions.

| Film behavior | Printing outcome |

|---|---|

| Even absorption | Smooth surface |

| Stable white layer | Strong opacity |

| Controlled drying | Clean edges |

| Poor coating | Grainy or cracked prints |

When film performance is stable, most “ink problems” simply disappear.

Hot peel vs cold peel DTF film: which should I choose?

I used to search for a universal answer. Real production testing taught me there isn’t one.

Hot peel film allows immediate peeling after pressing, while cold peel film requires cooling but offers greater transfer stability and detail retention.

Choosing peel type based on order type

Hot peel film3 is ideal for speed-focused production—simple logos, large volumes, consistent fabrics.

However, it demands precise temperature and pressure control. Minor deviations often cause edge lifting.

Cold peel film4 introduces a cooling step but reduces internal stress on the adhesive layer.

For complex artwork, fine text, or mixed fabric orders, cold peel consistently delivers higher reliability.

| Peel type | Best suited for | Main limitation |

|---|---|---|

| Hot peel | High-speed bulk jobs | Heat sensitivity |

| Cold peel | Detailed or mixed fabrics | Slower workflow |

The correct question is not “which is better,” but “which fits this order.”

Why DTF film is essential for production stability?

As order volume increases, small inconsistencies turn into expensive failures.

DTF film stabilizes the entire workflow by reducing static, improving transfer consistency, and protecting printers from contamination and rework.

DTF film as a production risk controller

Low-quality film introduces hidden costs:

- Printhead damage from film curl

- Powder contamination caused by static

- Increased reprints and labor waste

Once I standardized film quality, these variables dropped significantly.

Good film also lowers operator dependency—new staff can achieve acceptable results faster because the process becomes more forgiving.

Fabric compatibility also improves. Cotton, polyester, and blends respond differently to heat and stretch. Reliable film releases evenly and adapts better across fabric types.

| Production factor | With good film | With poor film |

|---|---|---|

| Failure rate | Low | High |

| Training effort | Reduced | High |

| Cost control | Predictable | Unstable |

At scale, DTF film is not a consumable—it is infrastructure.

How to select the right DTF film for consistent results

Choosing film should be intentional, not price-driven.

Key evaluation criteria include:

- PET thickness and heat stability

- Ink absorption uniformity

- Release force balance

- Anti-static back coating

- Compatibility with your ink and powder system

<!-- Internal Link: DTF Transfer Film Product Page -->

For production environments seeking consistent quality and repeatable results, understanding DTF transfer film specifications is critical.

You can review industrial-grade options here:

👉 https://yxcdtf.com/dtf-transfer-film/

Conclusion

DTF film is essential because it governs ink behavior, powder adhesion, peeling performance, and long-term durability—turning direct-to-film printing from an experimental process into a reliable, scalable production system.

Understanding PET's role in DTF film can help you choose better materials for printing, ensuring long-term dimensional stability. ↩

White ink stability depends heavily on ink-film interaction, not ink formulation alone. ↩

Hot peel film prioritizes speed but is less forgiving to process variation. ↩

Cold peel film improves bonding stability and fine detail protection. ↩