Many DTF prints look great on day one but crack, fade, or peel after washing. I faced this problem when customers started coming back with worn shirts.

The best DTF film for high-durability prints is a high-quality PET film with stable ink absorption, controlled release force, and strong compatibility with white ink and hot-melt powder.

When I stopped chasing cheap film and focused on durability testing, my rework rate dropped fast. That change reshaped how I choose DTF film today.

What makes a DTF print truly high-durability?

Many people think durability depends only on powder or press settings. I thought that too at first.

High-durability DTF prints depend on film stability, ink bonding, and release balance working together through repeated washing and stretching.

Durability starts before heat pressing

Durability1 begins at the printing stage. If the film coating absorbs ink unevenly, the ink layer becomes weak. Weak ink layers break first under washing stress. I test this by stretching printed film gently before powdering. Poor film already shows micro cracks.

The release layer also matters. A film that releases too easily creates a brittle adhesive layer. A film that releases too hard causes tearing during peel. High-durability film finds a balance, holding ink firmly during printing and releasing smoothly during transfer.

The PET base must resist heat shrinkage2. If PET shrinks during pressing, stress builds inside the design. This stress appears later as cracks.

For production-grade durability, the film base itself matters.

👉 DTF Transfer Film

| Durability factor | Role in lifespan |

|---|---|

| Ink absorption | Strong ink bonding |

| Release control | Flexible transfer layer |

| PET stability | Reduced internal stress |

I learned that durability is engineered, not accidental.

Which type of DTF film lasts longest after washing?

I tested many films by washing the same design over and over. The differences became clear.

Cold peel DTF film generally delivers higher durability than hot peel film because it reduces stress on the adhesive layer during transfer.

Why cold peel improves durability

Cold peel film3 allows the adhesive layer to cool and set fully before peeling. This creates stronger bonding between ink, powder, and fabric fibers. When I rushed peeling on hot peel film, edges lifted more often after washing.

Hot peel film4 still works for durability, but only with strict temperature and pressure control. Any variation weakens the bond.

Cold peel film also performs better on elastic fabrics. Stretch tests show fewer cracks after repeated pulls.

| Film type | Wash resistance | Stretch resistance |

|---|---|---|

| Cold peel | Very high | High |

| Hot peel | Medium to high | Medium |

For high-durability orders, I choose cold peel almost every time.

How does DTF film coating affect long-term durability?

Film coating is invisible, so many people ignore it. I stopped ignoring it after failed durability tests.

DTF film coating controls ink penetration, white ink stability, and adhesive bonding, which directly affects crack resistance and wash life.

Ink-receiving and release coatings

The ink-receiving layer5 must hold ink evenly without trapping moisture. Trapped moisture creates weak spots that fail after washing. I see this when prints feel rubbery instead of flexible.

The release coating6 must leave a clean interface. Residue from poor release layers causes stiff prints that crack early.

Anti-static back coating also helps durability. Static attracts excess powder, creating thick adhesive edges that break first.

These coating differences are most visible when comparing professional-grade films.

👉 DTF Transfer Film for Stable Production

| Coating feature | Durability impact |

|---|---|

| Even ink layer | Fewer cracks |

| Clean release | Soft hand feel |

| Anti-static | Uniform adhesion |

I now test coating quality before running large orders.

Is double-side matte DTF film better for durability?

I switched to double-side matte film after fighting static and powder issues.

Double-side matte DTF film improves durability by reducing static, improving powder control, and maintaining even heat distribution during pressing.

Why surface finish matters

Glossy back surfaces build static. Static pulls powder into unwanted areas, creating weak edges. Double-side matte film7 reduces this risk.

Matte surfaces also improve film feeding. Flat feeding prevents uneven ink layers, which protects durability.

During heat press, matte film distributes heat more evenly. Even heat means even melting of powder and stronger bonding.

| Film surface | Durability result |

|---|---|

| Single-side glossy | Higher failure risk |

| Double-side matte | Stable long-term wear |

This small change gave me more consistent wash test results.

How do I choose the best DTF film for durable production?

I stopped choosing film based on price. I choose based on testing and repeatability.

The best DTF film for high-durability prints is one that matches ink, powder, fabric type, and production environment through real testing, not claims.

My durability testing routine

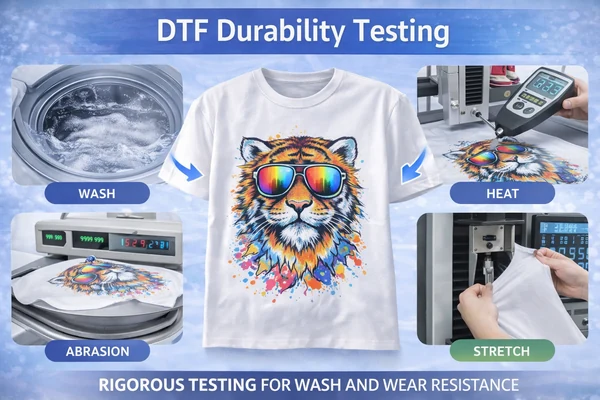

I test film using one design, one ink set, and one powder. I change only the film. I wash each sample at least ten cycles and stretch it after each wash.

I check edges first. Edge lifting always appears before center cracks. I also feel the hand. Durable prints stay soft.

I keep records of press temperature8, time, and pressure. Durable film stays stable even when small errors occur.

| Test step | What I observe |

|---|---|

| Initial peel | Clean release |

| Wash cycle | Crack resistance |

| Stretch test | Flexibility |

| Edge check | Adhesion strength |

This routine protects my reputation and profit.

Conclusion

The best DTF film for high-durability prints is a stable cold peel, double-side matte PET film with balanced coatings that protect ink bonding, flexibility, and wash resistance over time.

Understanding durability factors can help you choose better materials for your printing projects. ↩

Exploring this topic will provide insights into preventing design stress and ensuring quality in your prints. ↩

Explore the advantages of cold peel film for stronger bonds and better performance on elastic fabrics. ↩

Learn about the durability differences between hot and cold peel films to make informed choices for your projects. ↩

Understanding the ink-receiving layer is crucial for achieving high-quality prints without moisture issues. ↩

Exploring the role of release coating can help you improve print quality and prevent cracking. ↩

Explore this link to understand how double-side matte film can enhance your printing quality and reduce static issues. ↩

Learn about the impact of press temperature on print quality to enhance your printing process. ↩